Introduction

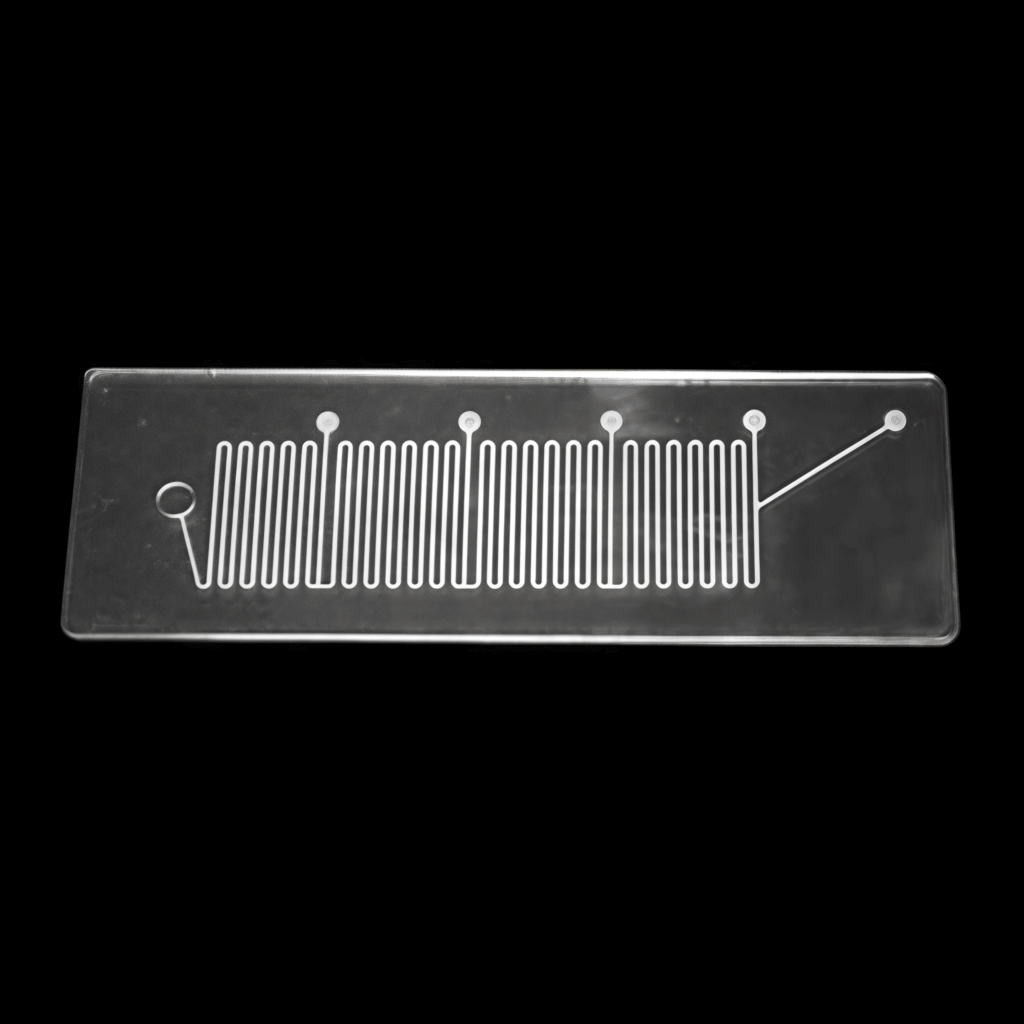

Our Tempered Soda-lime Sight Glass for Pressure Vessels is a high-performance solution tailored for industrial environments where safety and clarity are paramount. Manufactured from premium float glass and subjected to a rigorous tempering process, this sight glass achieves exceptional strength and durability. It is specifically engineered to withstand mechanical stress, sudden temperature changes, and the operational demands of pressure vessels. The combination of excellent optical transparency and robust construction ensures that operators can safely and accurately monitor internal conditions. Flexible customization services are available to meet project-specific needs, ensuring seamless integration with a wide range of equipment.

Features

- High-quality float glass construction

- Fully tempered for enhanced strength and impact resistance

- Excellent optical clarity for precise visual monitoring

- Superior thermal shock resistance

- Available in custom shapes, sizes, and edge finishes

- Smooth surface with high scratch resistance

- Dimensional accuracy for easy installation

Advantages

- Exceptional Safety Performance: Tempering increases the glass’s mechanical strength by up to five times compared to non-tempered glass, providing reliable protection in high-pressure environments.

- Thermal & Mechanical Durability: Specifically designed to endure rapid temperature fluctuations and continuous mechanical stress, ensuring long-term stability and performance.

- Precision & Compatibility: Accurate sizing and diverse edge processing options guarantee compatibility with various pressure vessel designs and mounting requirements.

- Reduced Maintenance & Replacement Costs: Enhanced durability minimizes the risk of breakage and surface wear, extending service life and reducing downtime.

- Custom Manufacturing Flexibility: Our OEM/ODM capabilities allow us to deliver tailored solutions that align with your specific technical and design requirements, enhancing project efficiency and value.

Benefits

- Enhanced Safety for Critical Equipment: Reduces operational risks by providing a strong, impact-resistant barrier that maintains clarity and integrity under pressure.

- Clear Visual Access for Monitoring: High transparency ensures operators can perform accurate inspections without equipment disassembly, improving workflow efficiency.

- Ease of Installation & Integration: Customizable dimensions and edge treatments simplify the installation process, saving time and reducing potential fitting issues.

- Reliable Performance in Harsh Conditions: Maintains optical and structural properties even in challenging environments, supporting consistent and safe operation.

- Professional Support & Flexible Supply: With a minimum order quantity of 500 units and strong customization services, we provide responsive and reliable support for both standard and specialized projects.

Application

Widely used in pressure vessels, industrial equipment observation windows, instrument viewports, and sealed systems requiring robust, transparent sight glasses capable of withstanding mechanical and thermal stress.