Introduction

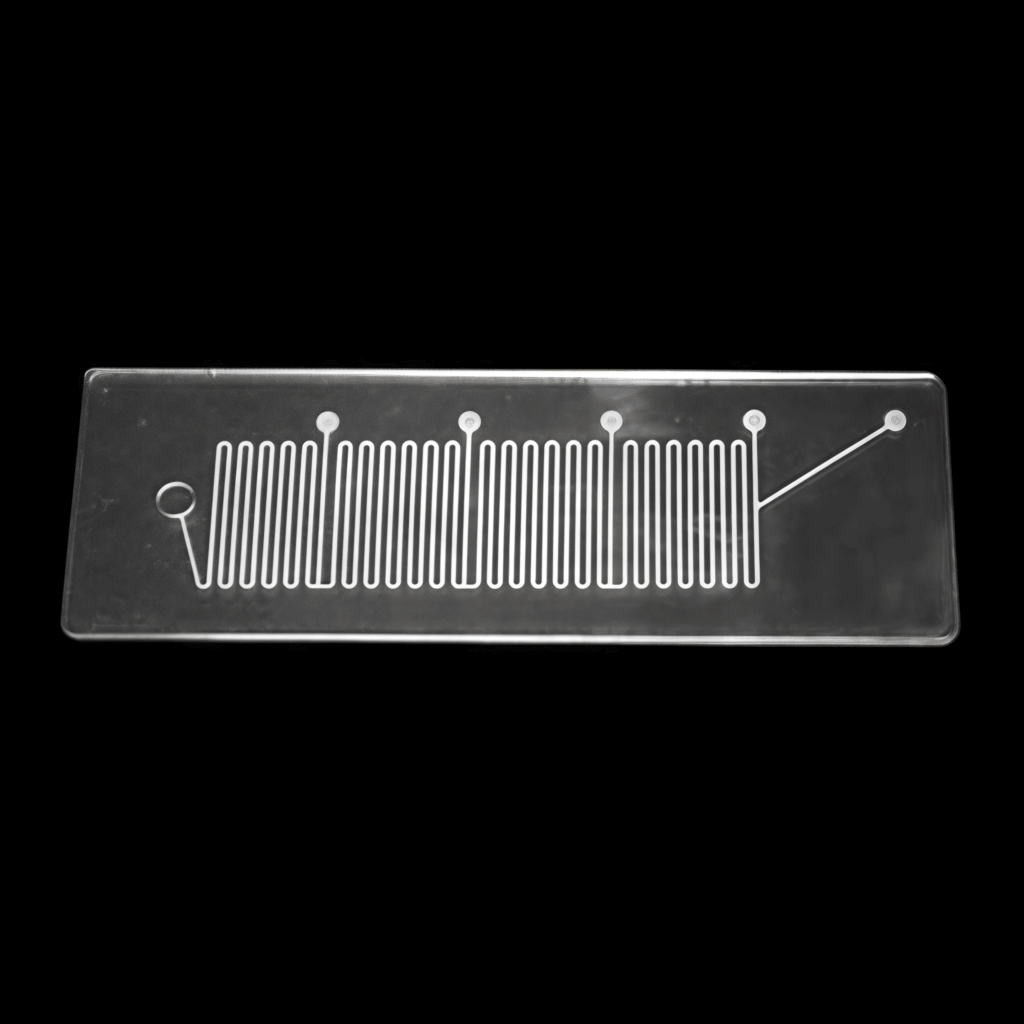

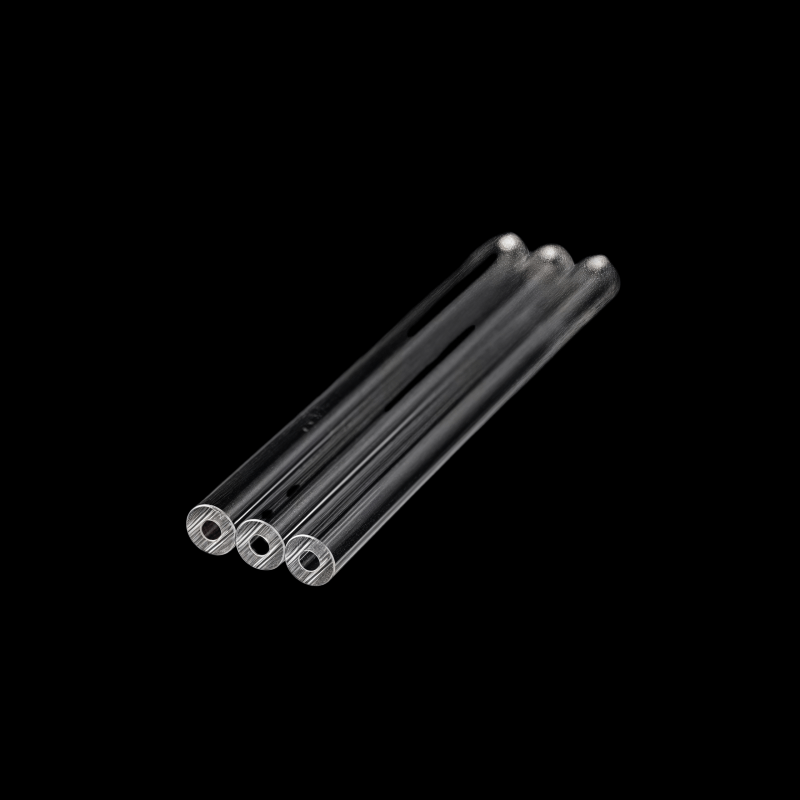

Our quartz microfluidic glass slide is crafted from premium fused silica, a material known for its outstanding purity and exceptional physical properties. Through advanced precision processing, the slide is engineered to provide a flawless surface with exact dimensional control, ensuring reliable performance in microfluidic devices and high-sensitivity analytical systems. The slide’s superior chemical resistance and thermal stability make it highly suitable for use in environments involving aggressive chemicals or extreme temperature variations.

Features

- High-Purity Fused Silica: Guarantees excellent optical transparency and minimal background interference in optical or spectroscopic analyses.

- Precision Processing: Achieves tight tolerances and smooth surfaces critical for microfluidic channel integration and fluid control.

- Chemical Inertness: Resistant to most acids, bases, and solvents, maintaining slide integrity and sample purity.

- Thermal Stability: Withstands rapid temperature fluctuations without cracking or deformation.

- Customizable Dimensions and Surface Treatments: Supports tailored shapes, sizes, and surface modifications to match specific application requirements.

Advantages

Compared to conventional glass slides, this quartz microfluidic slide offers enhanced chemical durability, improved optical clarity, and superior mechanical robustness. The precision manufacturing process ensures compatibility with complex microfluidic channel designs, enabling precise fluid manipulation at micro-scale levels. Its resistance to contamination and degradation over time makes it a reliable choice for long-term experiments and industrial processes. Additionally, customizable options empower clients to adapt the slide perfectly to their unique application demands, improving workflow efficiency and experimental accuracy.

Benefits

- Enhanced Experimental Accuracy: High optical clarity and chemical purity ensure reliable measurement and data collection.

- Durability and Longevity: Resistant to harsh chemicals and thermal shocks, reducing replacement frequency and downtime.

- Versatility: Ideal for biomedical research, chemical analysis, microfluidic device fabrication, and semiconductor applications.

- Custom Design Flexibility: Enables tailored solutions that meet exact client specifications, improving integration and performance.

- Ease of Maintenance: Smooth, inert surfaces facilitate easy cleaning and reduce risk of contamination.

Application

Widely used in microfluidic device fabrication, biomedical research, chemical analysis, and semiconductor manufacturing. It supports precision fluid handling, high-resolution imaging, and chemical processing in advanced scientific and industrial environments.