Introduction

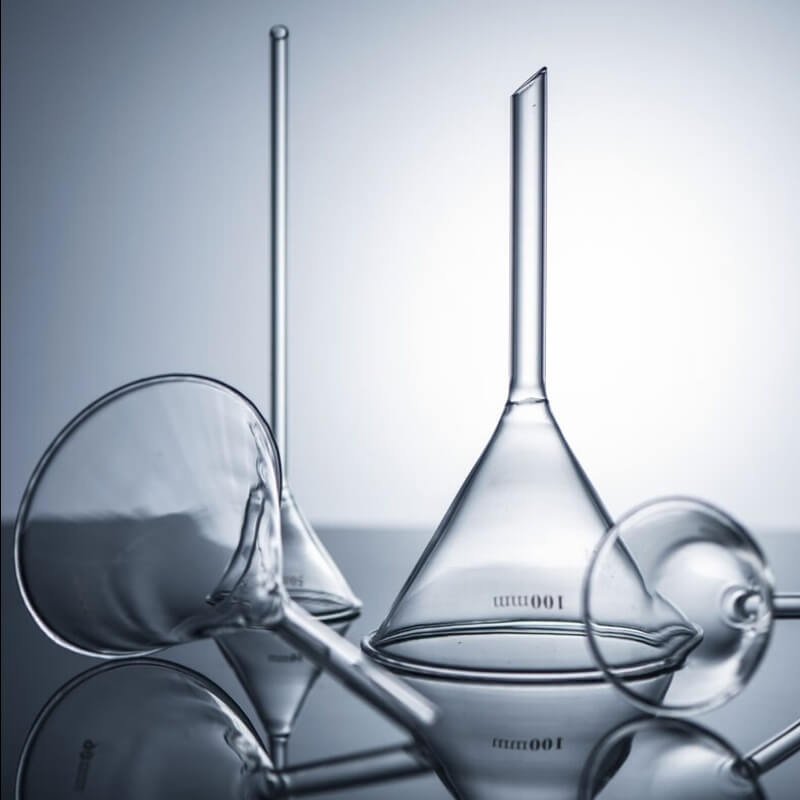

Our quartz glass funnel is manufactured from premium fused silica, renowned for its superior purity and outstanding physical properties. Utilizing skilled flameworking craftsmanship, this funnel is shaped with precision to ensure smooth fluid flow and reliable performance in sensitive laboratory procedures and high-purity industrial processes. Its exceptional chemical inertness and thermal resistance make it suitable for handling aggressive solvents, acids, and temperature-sensitive liquids without risk of contamination or damage.

Features

- High-Purity Fused Silica Material: Ensures maximum chemical resistance and minimal interaction with fluids, preserving sample integrity.

- Flameworking Process: Produces precise dimensions, smooth surfaces, and consistent wall thickness for reliable performance.

- Thermal Stability: Resistant to rapid temperature changes and capable of operating under high or low temperature conditions.

- Customizable Design: Supports tailor-made specifications including shape, size, diameter, and surface finish to suit specific laboratory or industrial requirements.

- Durable and Lightweight: Combines robustness with ease of handling for enhanced user convenience.

Advantages

Compared with standard glass funnels, the quartz glass funnel offers superior resistance to chemical corrosion and thermal shock, significantly extending its operational lifespan. The precision flameworking process guarantees dimensional accuracy and smooth edges, reducing the risk of spills and improving flow control. Its compatibility with high-purity and aggressive chemical environments ensures safer, contamination-free handling, critical in pharmaceutical, chemical, and research applications. Moreover, customizability allows integration into complex setups, meeting unique client demands and enhancing workflow efficiency.

Benefits

- Enhanced Safety and Reliability: High thermal and chemical stability minimize risks during transfer processes.

- Optimized Fluid Handling: Smooth internal surfaces and precise dimensions improve flow rates and reduce clogging.

- Versatility: Ideal for applications in laboratories, chemical synthesis, semiconductor manufacturing, and pharmaceutical production.

- Custom Solutions: Flexible customization meets diverse operational requirements, supporting a wide range of experimental and industrial workflows.

- Easy Maintenance: Quartz’s smooth surface resists deposits and contamination, simplifying cleaning and prolonging usability.

Application

Widely used in laboratory experiments, chemical processing, pharmaceutical manufacturing, and semiconductor industries for accurate and safe liquid or powder transfer. Its superior material properties and customizable design make it indispensable for high-precision and high-purity operations.