Introduction

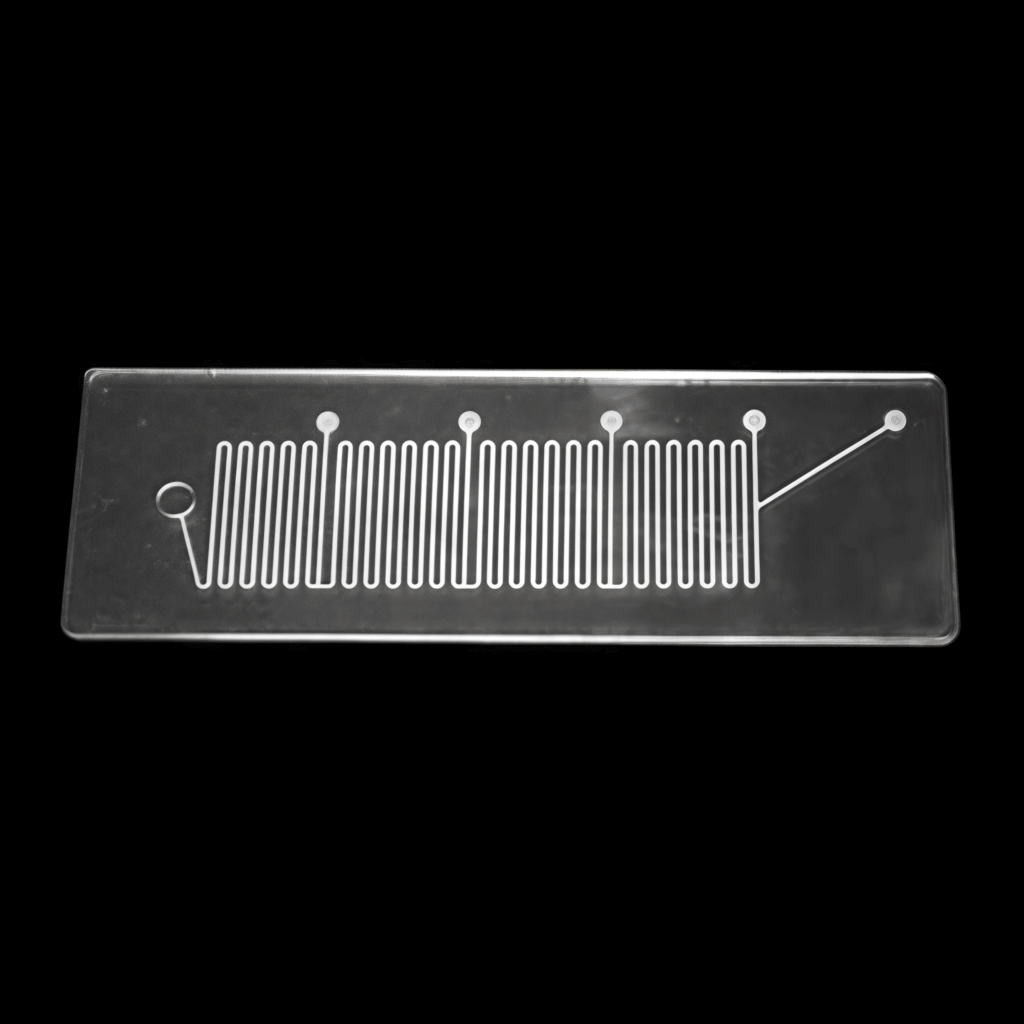

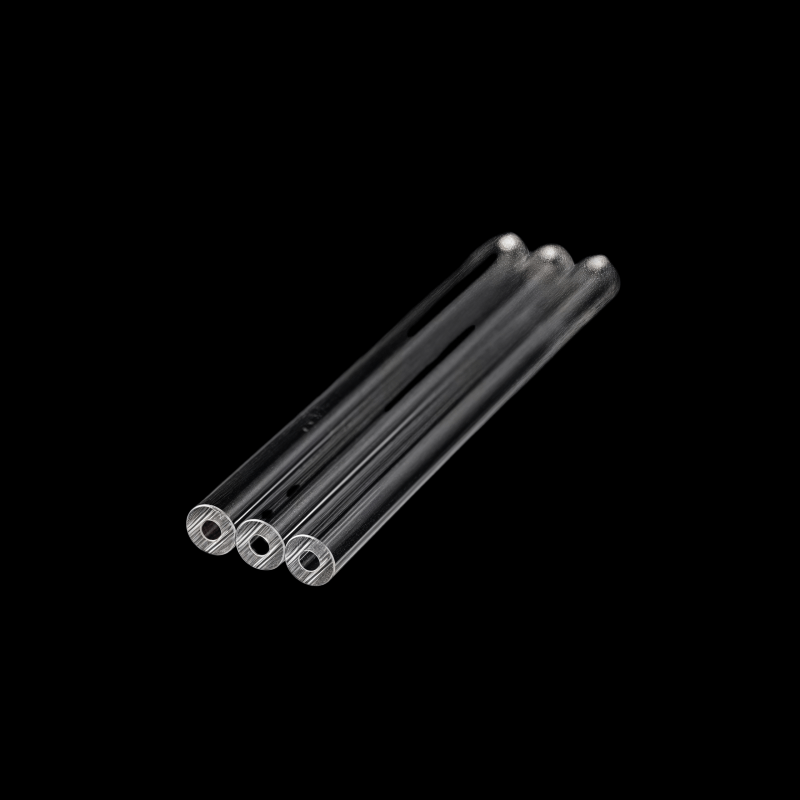

Our quartz boats and baskets are precision-crafted through advanced flameworking techniques to support the demanding requirements of silicon wafer cleaning processes. Engineered for compatibility with wet chemical cleaning, thermal treatments, and high-purity environments, these quartz handling solutions ensure contamination-free processing and safe handling of delicate wafers.

Features

- High-Purity Quartz Material: Excellent resistance to acids, alkalis, and thermal shock, making it ideal for semiconductor-grade applications.

- Precision Flameworking: Guarantees dimensional accuracy, smooth surfaces, and robust structural integrity.

- Versatile Configurations: Available in both boat and basket forms, designed to accommodate various wafer sizes and quantities.

- Superior Thermal Stability: Maintains performance under extreme temperatures, supporting both wet and dry cleaning processes.

- Customizable Specifications: Shape, dimensions, and surface treatments are fully customizable based on customer drawings and samples.

Advantages

Compared to alternative materials, quartz boats and baskets offer unmatched purity and longevity. Their chemical inertness prevents contamination of silicon wafers during critical cleaning steps. Enhanced durability reduces breakage rates, ensuring safer and more efficient wafer handling. Tailor-made solutions allow for seamless integration into existing production lines.

Benefits

- Optimal Process Compatibility: Suitable for HF, H2SO4, H2O2, and other aggressive cleaning agents used in wafer processing.

- Enhanced Yield & Product Quality: Minimizes contamination risks, contributing to higher semiconductor yield rates.

- Durable & Cost-Efficient: Long service life reduces operational costs associated with frequent replacements.

- Full Customization Support: Our team provides professional customization services to meet precise technical and operational requirements.

- Reliable Supplier for High-Tech Industries: Trusted by semiconductor manufacturers for delivering consistent product quality and service.

Application

Widely used in semiconductor wafer cleaning, including wet chemical processes, RCA cleaning, thermal treatments, and other high-purity applications in the electronics and photovoltaic industries.