Introduction

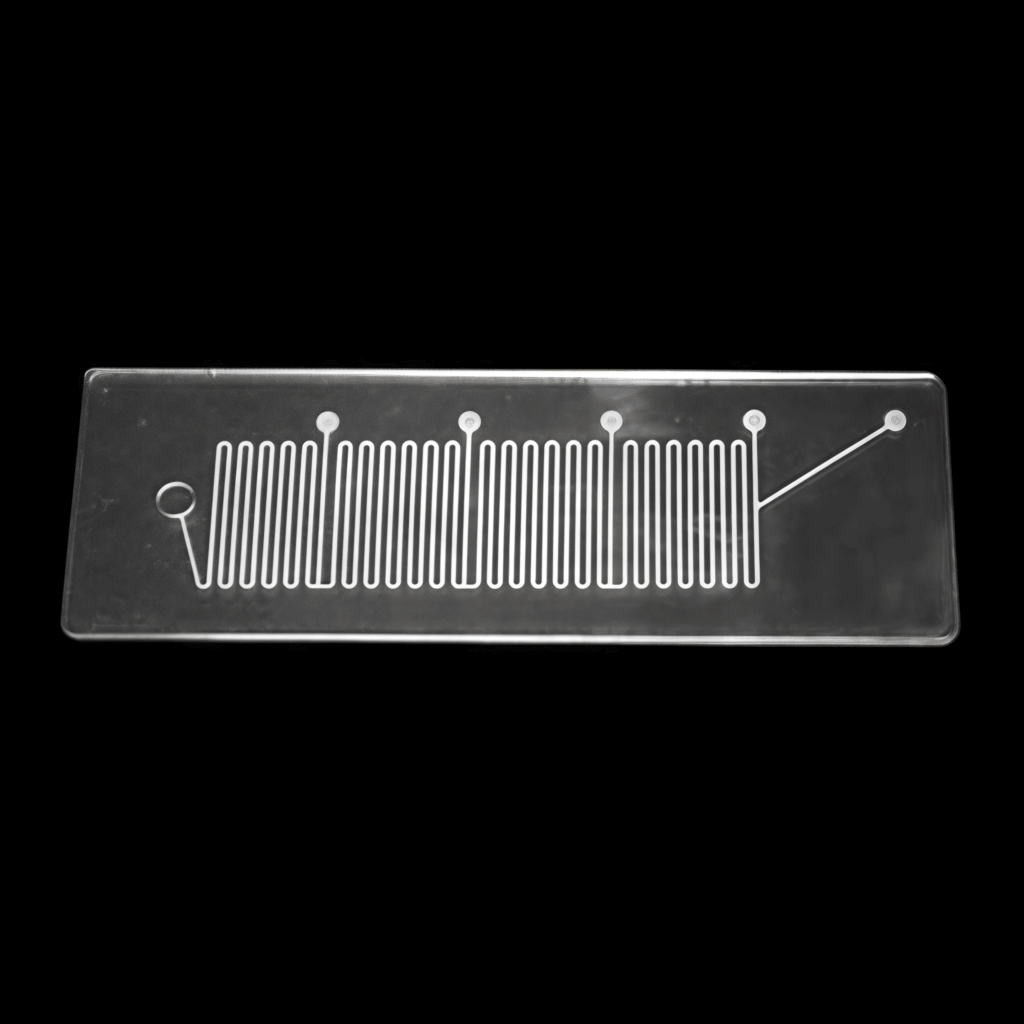

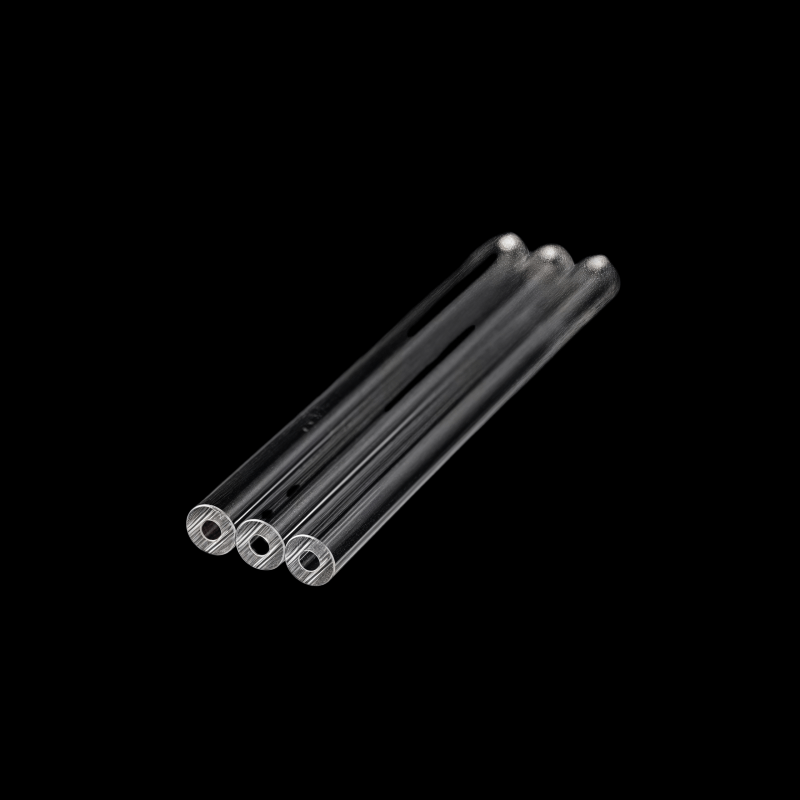

The Multi Lens Arrays for LED / Laser are engineered for high-precision optical systems that demand compactness, beam consistency, and minimal alignment tolerances. Manufactured using advanced mould pressing techniques, these arrays integrate multiple lenses onto a single borosilicate glass substrate, ensuring optimal positioning and eliminating the need for complex assembly processes.

Features

- Material: Borosilicate glass

- Manufacturing Process: Mould pressed integration of multiple lenses onto a single substrate

- Design: Multi-element configuration for precise beam shaping and control

- Thermal Resistance: Exceptional stability under high-temperature environments, compatible with LED and laser light sources

- Optical Performance: High transmittance, low optical distortion, and superior uniformity

Advantages

- Integrated Design: Eliminates the need for separate lens alignment, improving system stability and reducing assembly time

- Compact & Efficient: Optimized for compact optical systems requiring multiple beams or precise collimation

- Durability: Resistant to yellowing, UV degradation, and environmental wear

- Low Maintenance: Long-lasting optical clarity reduces maintenance costs over time

Benefits

- Achieves consistent, high-quality beam shaping for LED, laser, or projection systems

- Enhances system efficiency and reliability in automotive lighting, digital projectors, and high-power illumination devices

- Supports custom optical patterns and beam configurations based on project requirements

Application Scenarios

- Digital projectors

- Automotive LED / laser headlamps

- High-power LED or laser-based illumination systems

- Industrial machine vision and sensing

Customization Options

- Customizable shape, size, pattern, optical characteristics, and coatings according to customer drawings or samples

MOQ

- 500 pieces