Introduction

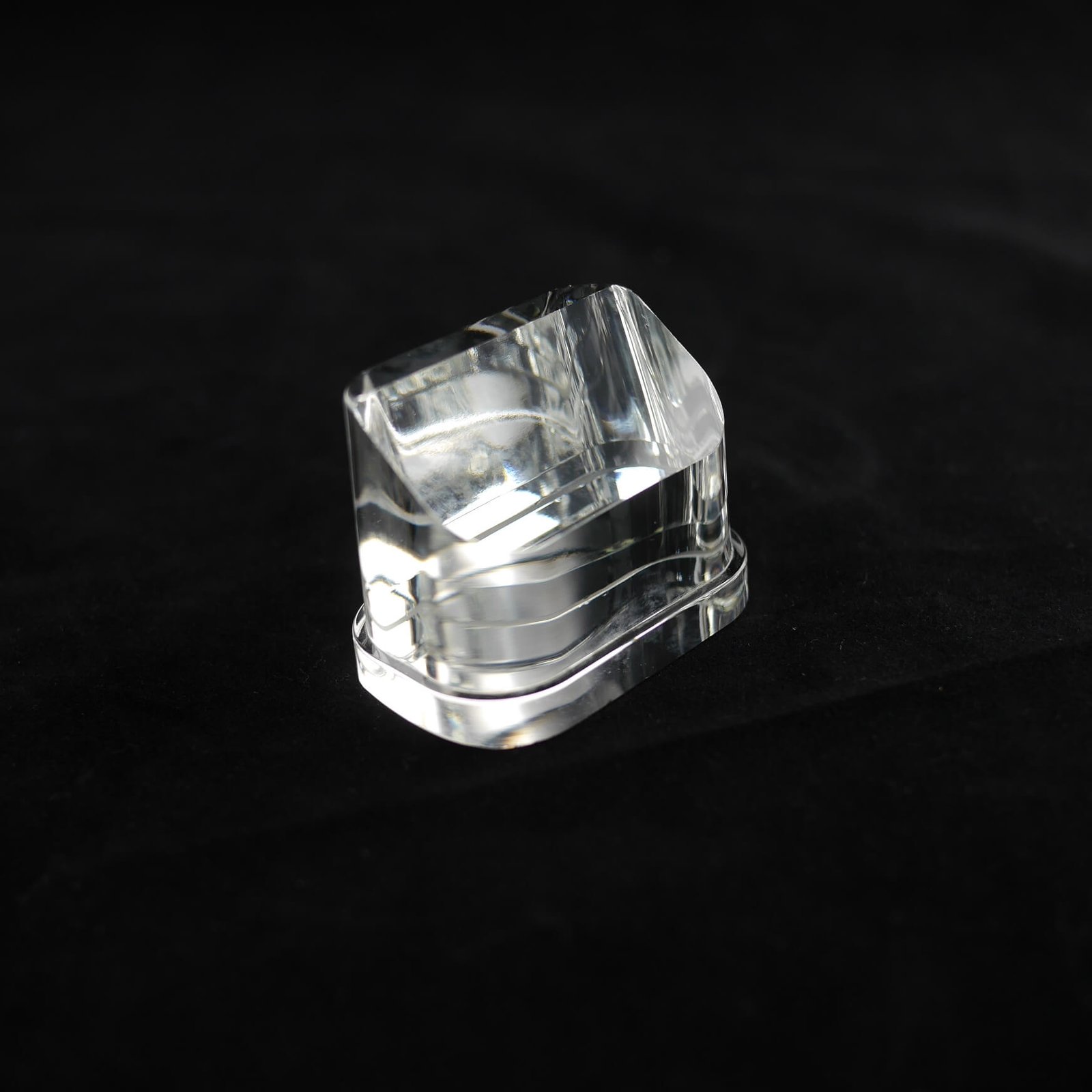

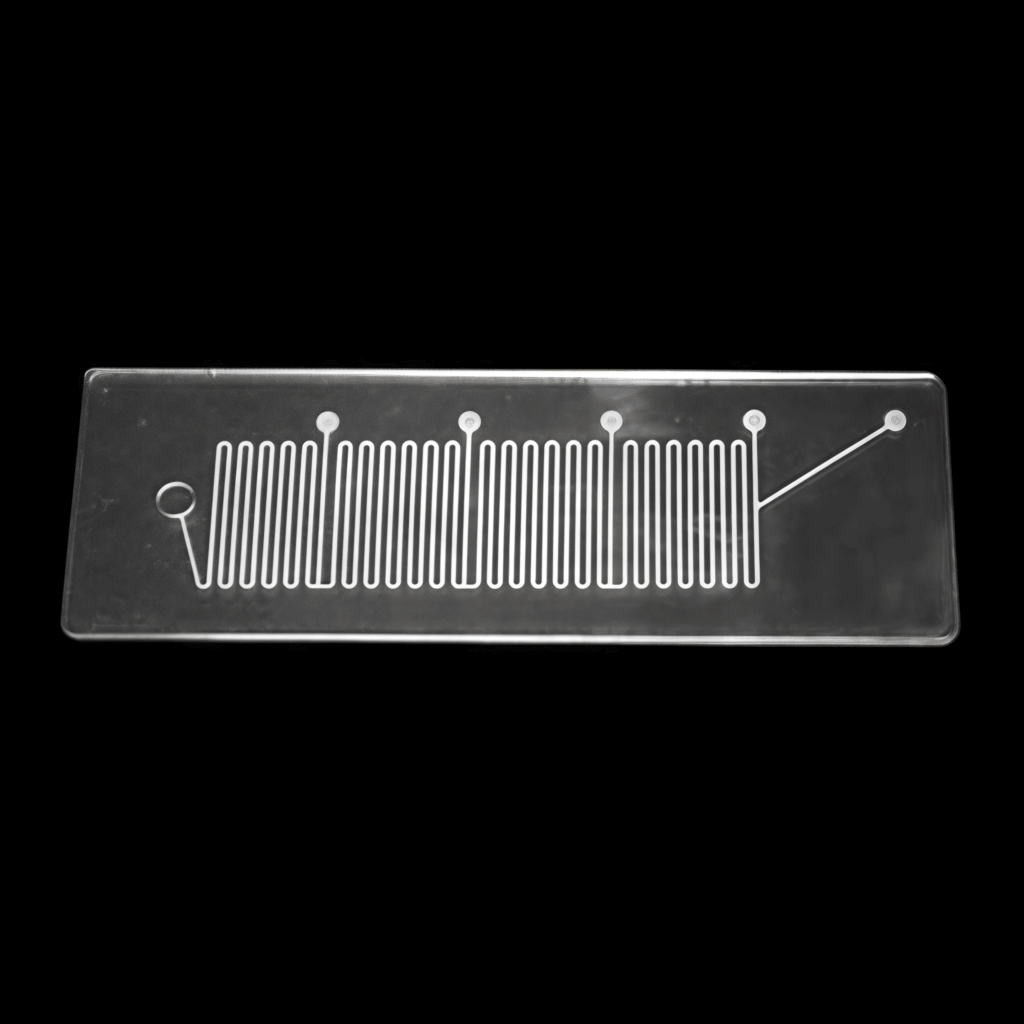

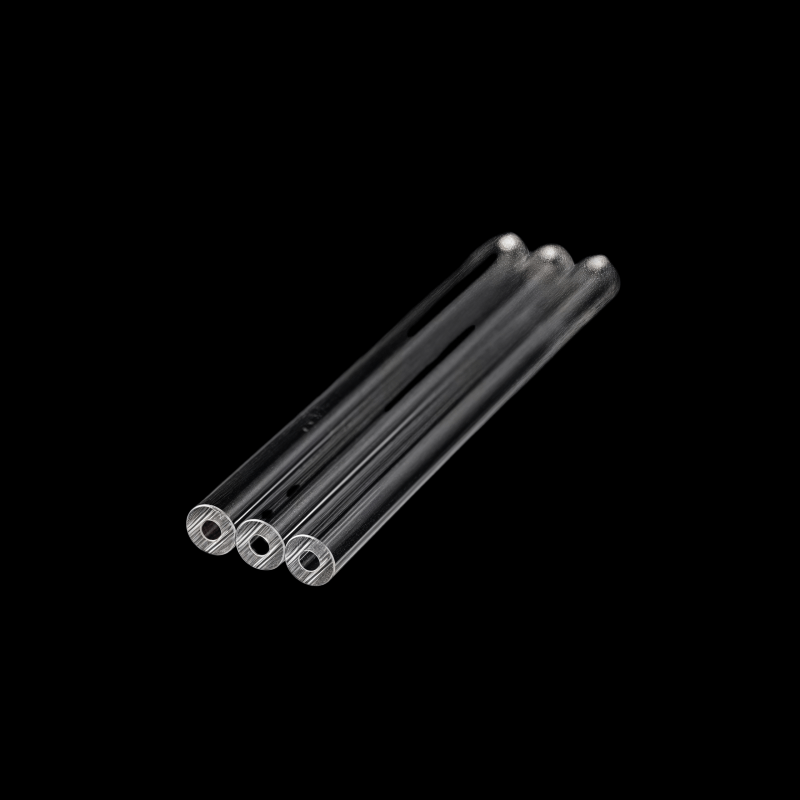

The Glass Prisms for Airfield and Runway are high-precision optical components manufactured from borosilicate glass using mould pressing technology. Designed specifically for aviation and airfield lighting systems, these prisms offer superior optical clarity, durability, and reliability in the harshest outdoor environments. Their robust design ensures optimal light distribution and enhances runway safety, even in extreme weather conditions.

Features

- Material: Borosilicate glass

- Manufacturing Process: Mould pressed with precision surface finishing

- Optical Performance: High transmittance, uniform light distribution, available in anti-glare designs

- Thermal & Weather Resistance: Withstands high temperatures, UV exposure, and harsh weather conditions without deformation or discoloration

- Durability: Scratch resistant, anti-yellowing, low maintenance over extended operational life

Advantages

- Stable Performance: Maintains consistent optical performance over time, reducing the need for frequent replacements

- Anti-Glare Option: Optional anti-glare textures or coatings to optimize visibility and reduce pilot glare during takeoff and landing

- High Light Efficiency: Ensures bright, uniform illumination critical for runway and taxiway safety

- Customization Flexibility: Can be tailored to meet specific project requirements, including shape, size, surface pattern, color, and optical effects

Benefits

- Enhances visibility and safety in airfield and runway lighting applications

- Performs reliably in extreme environments (high heat, humidity, salt exposure, wind, and UV)

- Reduces maintenance and operational costs due to long-lasting durability and stable performance

Application Scenarios

- Runway centerline and edge lights

- Taxiway lights

- Airfield obstruction and guidance lights

- Apron and helipad lighting systems

Customization Options

- Customizable in shape, size, color, optical effect, and surface pattern according to client specifications or supplied samples