Introduction

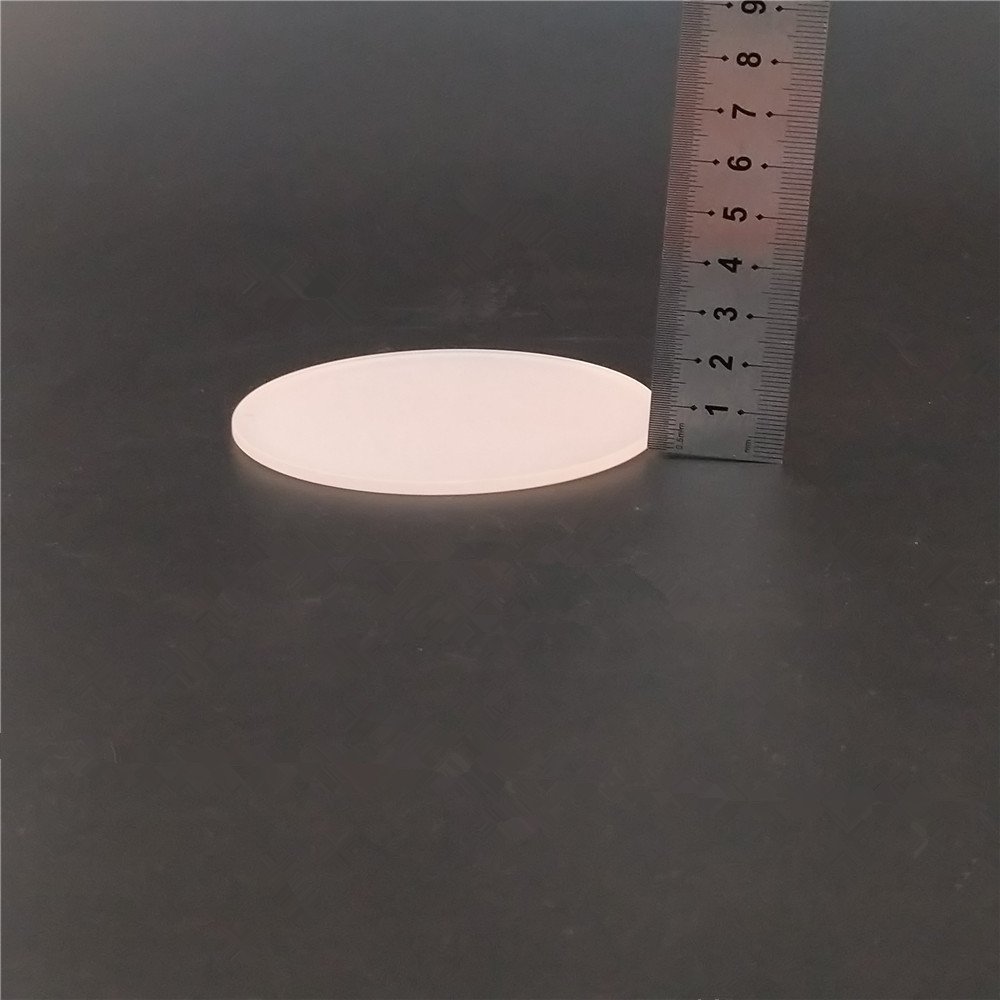

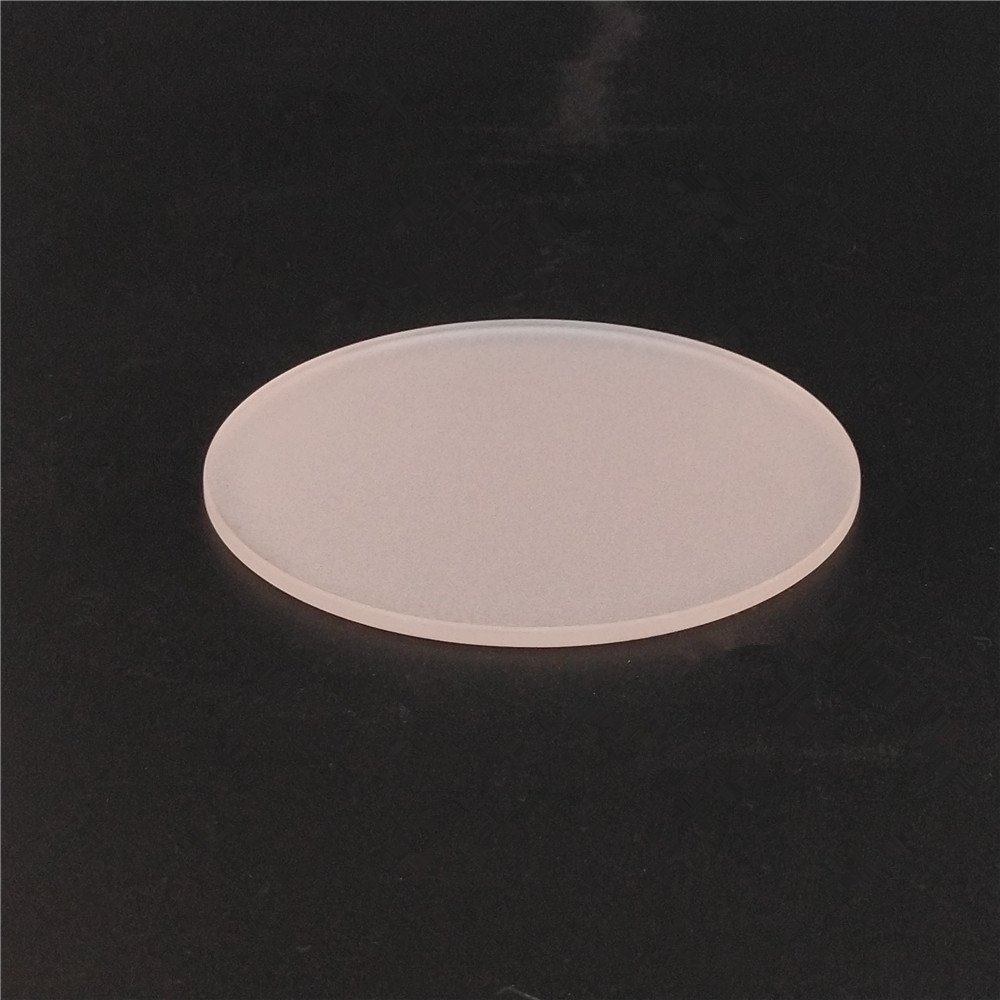

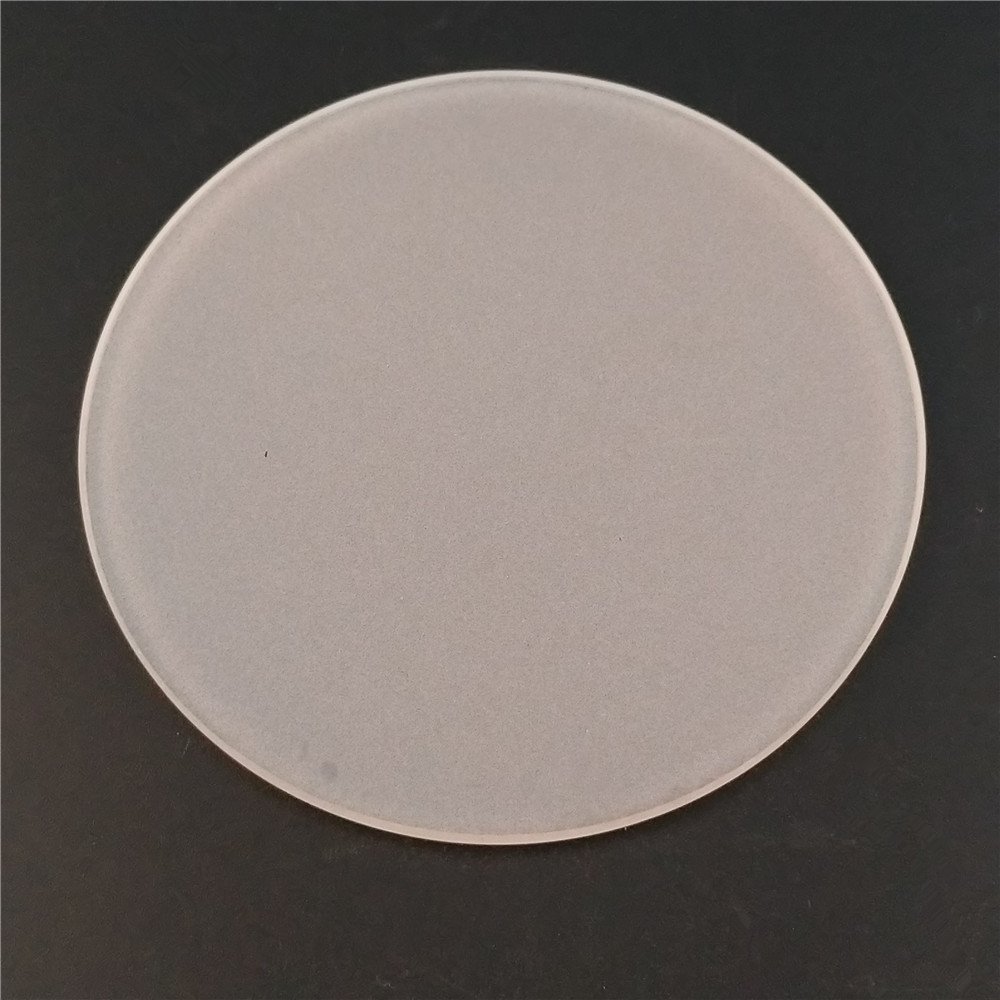

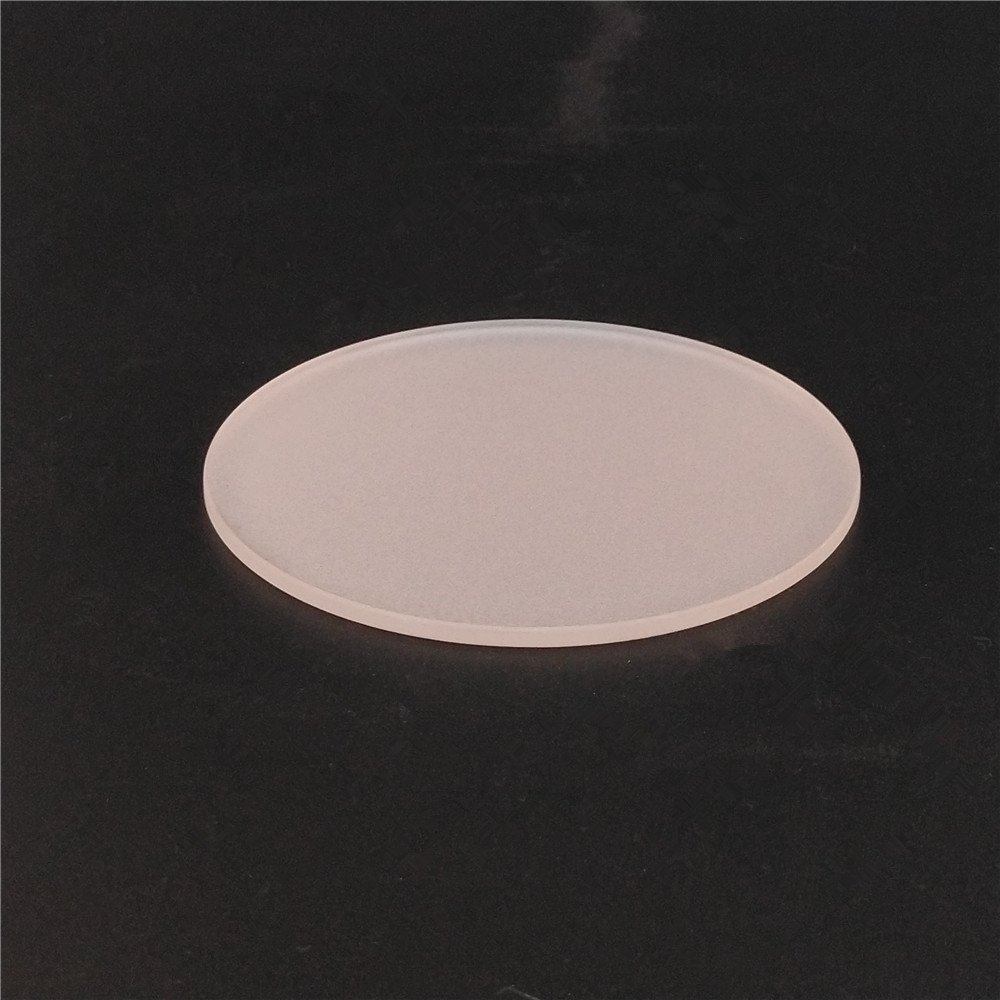

Engineered for superior optical performance, our frosted glass diffuser transforms harsh light into soft, uniform illumination. The low-iron glass base material ensures minimal color distortion, while the dual-process treatment (sandblasting + tempering) creates a durable surface resistant to scratches and thermal stress. Unlike plastic alternatives, this glass diffuser won’t yellow or warp over time, maintaining consistent light quality for years.

Features

- Material Excellence:

- Ultra-clear low-iron glass (Fe₂O₃ <0.01%)

- Tempered to 100+ MPa surface compression

- Optical Control:

- Adjustable haze levels (30%-90%) via sandblasting grit control

- Optional double-sided frosting for maximum diffusion

- Customization:

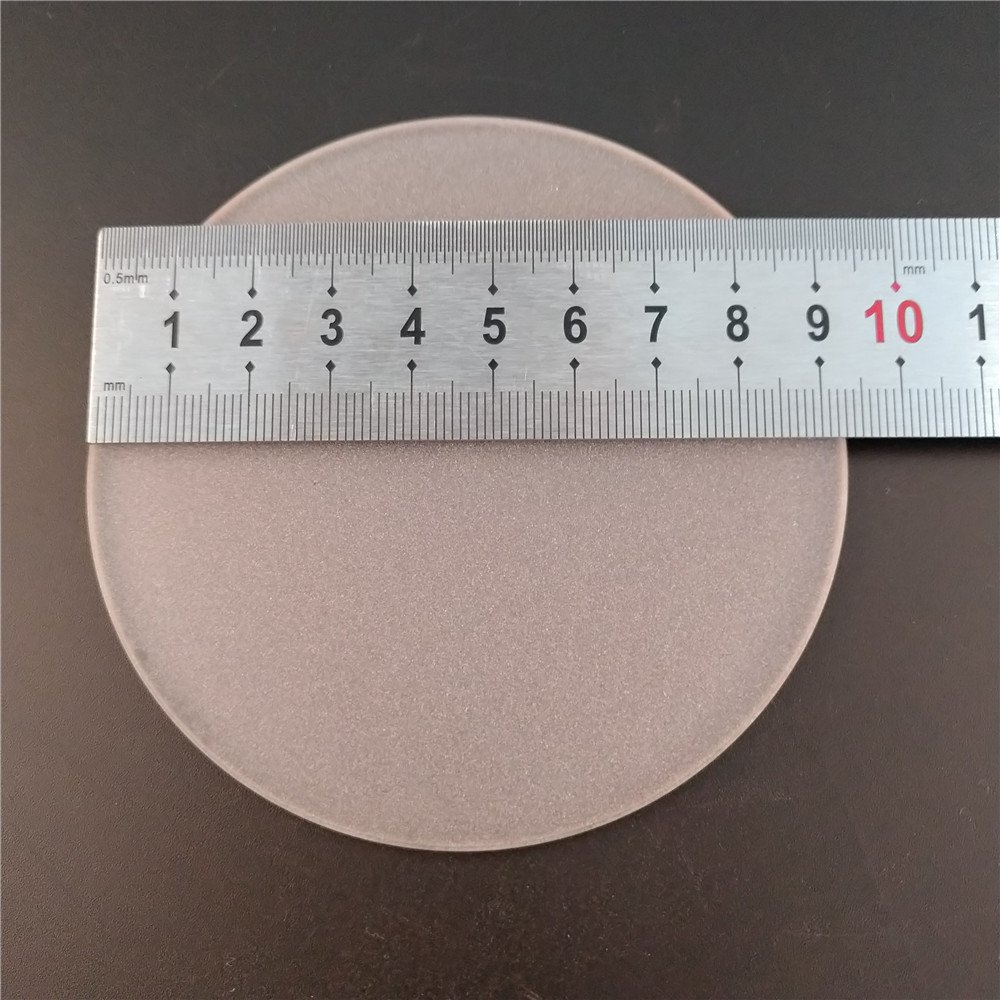

- CNC-cut shapes (circles, rectangles, polygons)

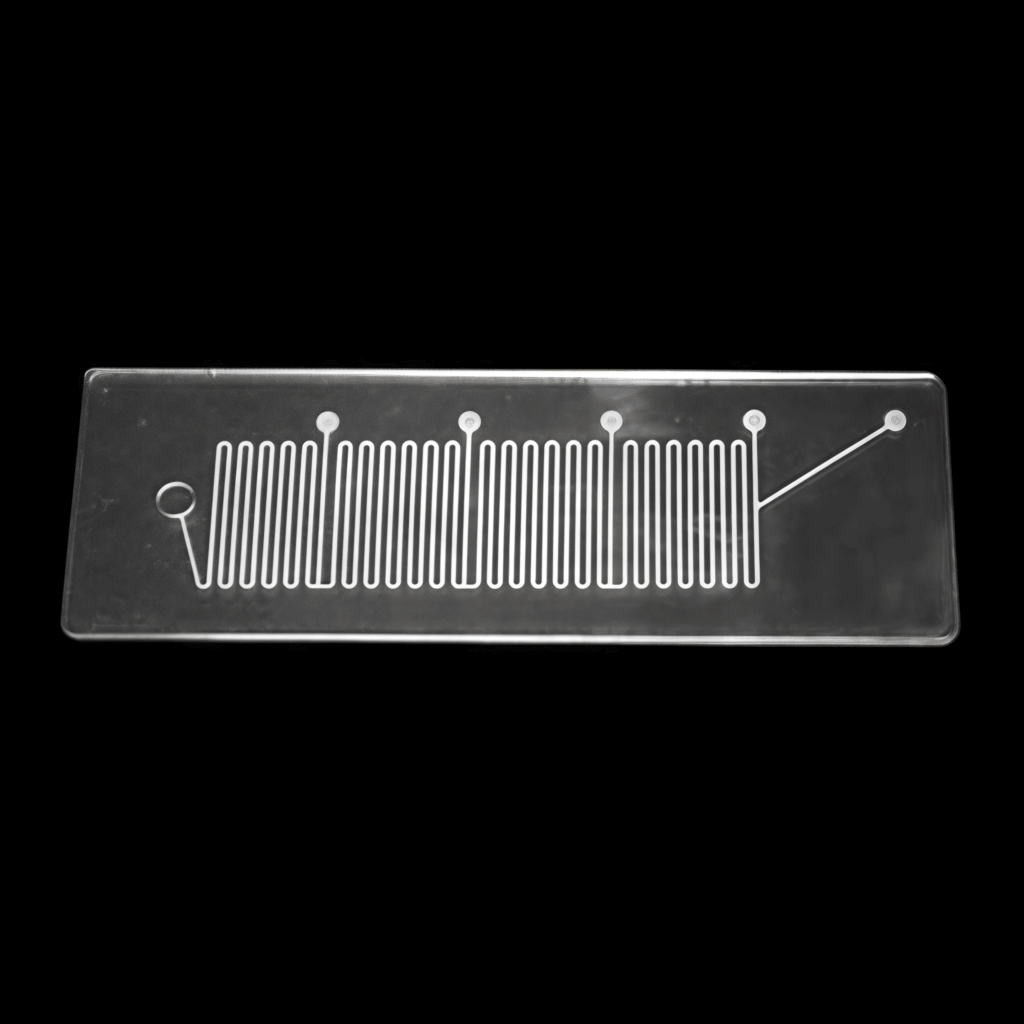

- Pattern sandblasting (logos, geometric designs)

- Edgework options (polished, seamed, pencil-edged)

- Safety Compliance:

- Breaks into harmless granules

Advantages

- Optical Performance

- 90% original light transmission (clear glass)

- Eliminates >95% of direct glare points

- Durability Advantages

- 4x more scratch-resistant than acrylic diffusers

- Withstands UV exposure without yellowing

- Resists common cleaning chemicals

- Design Flexibility

- Custom patterns achievable:

- Gradient density frosting

- Selective clear/frosted areas

- Micropatterns (50-200μm resolution)

- Thickness options: 2~19mm

- Custom patterns achievable:

- Safety & Compliance

- RoHS compliant material

Benefits

- Lighting Quality

- Creates museum-grade uniform illumination

- Reduces eye strain in office environments

- Enhances LED source blending

- Project Versatility

- Indoor applications:

- Office ceiling panels

- Retail display lighting

- Residential pendant lights

- Outdoor applications:

- Weather-resistant facade lighting

- Pool area luminaires

- High-humidity environment fixtures

- Indoor applications:

- Installation Advantages

- Pre-drilled holes available for mounting

- Compatible with:

- Aluminum frames

- Suspension systems

- Gasket-sealed enclosures

- Sustainable Choice

- 100% recyclable material

- 10+ year lifespan reduces replacements

- No VOC emissions

Application Examples

- Corporate:

- Office lobby light walls

- Conference room linear lights

- Hospitality:

- Hotel bar pendant clusters

- Restaurant partition lighting

- Residential:

- Kitchen island linear lights

- Bathroom mirror backlighting

- Commercial:

- Museum display case lighting

- Retail shelf illumination systems