Introduction

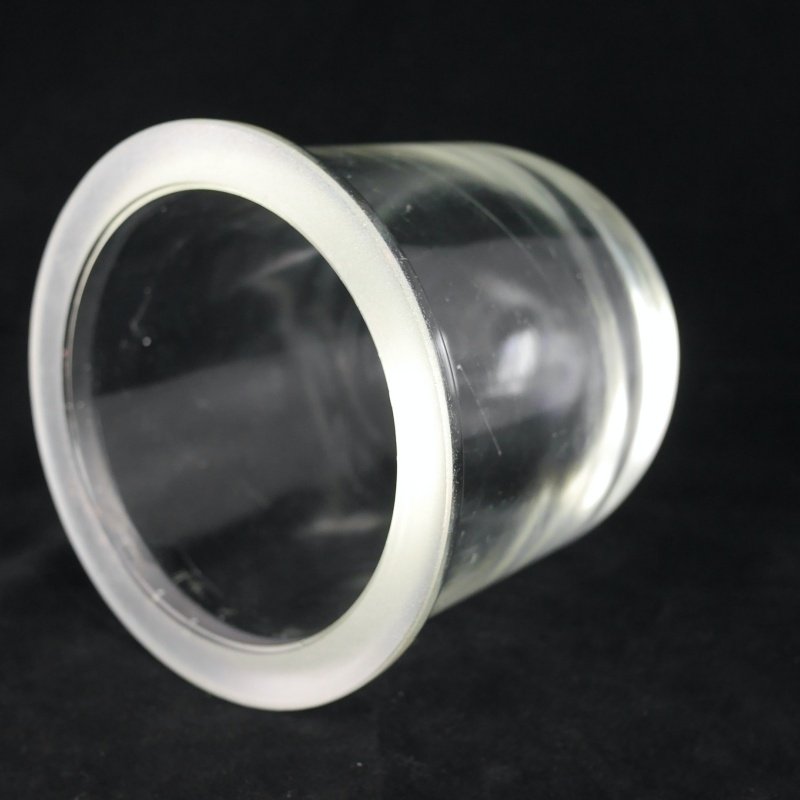

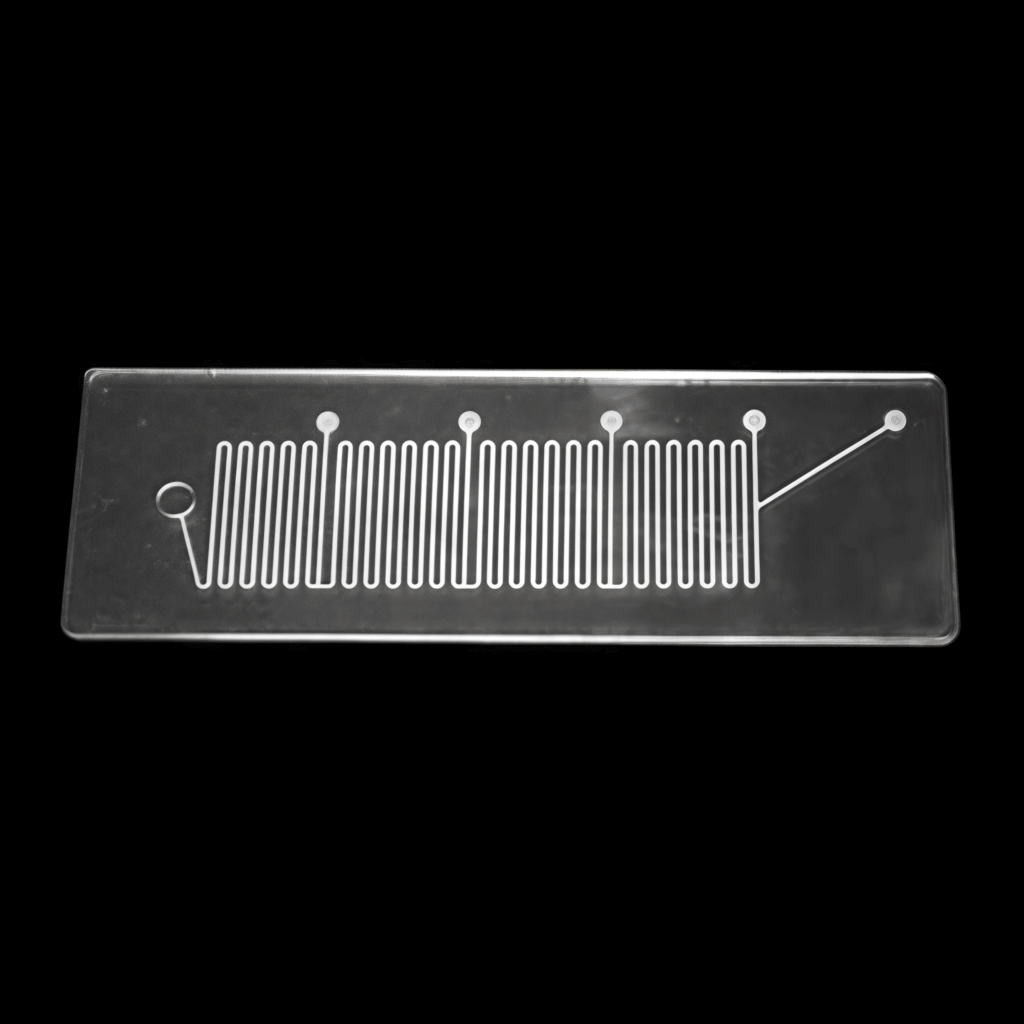

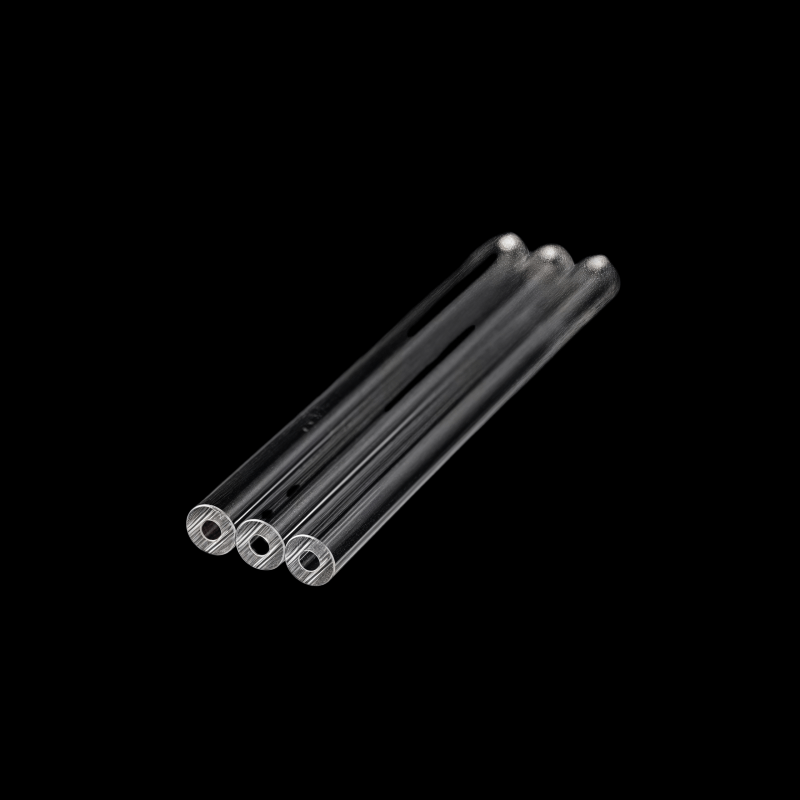

Designed to protect lighting systems in the most demanding industrial settings, our Explosion Proof Well Glass Dome combines advanced material science with robust engineering. The borosilicate glass construction provides superior resistance to thermal shock and chemical corrosion, while the mould-pressed manufacturing ensures uniform thickness and structural integrity. The domed shape enhances structural strength, and the flanged base allows for airtight sealing with gaskets or clamps, making it perfect for Zone 1 and Zone 2 hazardous areas.

Features

- High-transparency borosilicate glass (92% light transmission) for clear illumination

- Domed cylindrical design with reinforced flanged base for secure mounting

- Mould-pressed and tempered for enhanced mechanical strength

- Customizable in diameter (100-300mm), height (50-300mm), and thickness (6-15mm)

- Optional surface treatments: Anti-reflective, frosted, or prismatic finishes

Advantages

- Explosion-Proof Performance

- Can use in hazardous locations

- Withstands pressure waves from explosions without shattering

- Non-sparking design eliminates ignition risks

- Unmatched Durability

- Resists impacts for high-traffic industrial areas

- Thermal shock resistance (Δ300°C) ensures reliability in fluctuating temperatures

- Impervious to corrosive chemicals, including acids, alkalis, and solvents

- Optical Clarity & Efficiency

- Maintains 92% light transmission even after prolonged UV exposure

- Minimal light distortion for accurate color rendering in critical applications

- Optional anti-reflective coating reduces glare and light loss

- Design & Customization Flexibility

- Tailored dimensions to fit existing fixtures or custom designs

- Laser etching for permanent labeling or branding

- Compatibility with various sealing systems (silicone, Viton®, or PTFE gaskets)

Benefits

- Enhanced Safety in Hazardous Environments

- Prevents explosive atmospheres from igniting, protecting personnel and equipment

- Granular fragmentation ensures safe failure mode

- Reduces maintenance frequency in hard-to-access locations

- Cost-Effective Longevity

- 5-10 year lifespan in harsh conditions, outperforming polycarbonate alternatives

- Lower replacement costs due to superior breakage resistance

- Energy-efficient design maximizes luminaire output

- Easy Installation & Maintenance

- Flanged base simplifies sealing and mounting processes

- Lightweight yet sturdy construction reduces handling risks

- Self-cleaning surface options minimize dirt accumulation

- Regulatory Compliance

- Meets international standards

- Documentation support for safety audits and certifications

- Traceable batch testing for quality assurance

Application

- Oil & Gas: Offshore platform lighting, refinery explosion-proof fixtures

- Mining: Underground tunnel luminaires, extraction area lighting

- Chemical Plants: Reactor area lighting, storage tank illumination

- Utilities: Power plant hazardous zone lighting, wastewater treatment facilities