Introduction

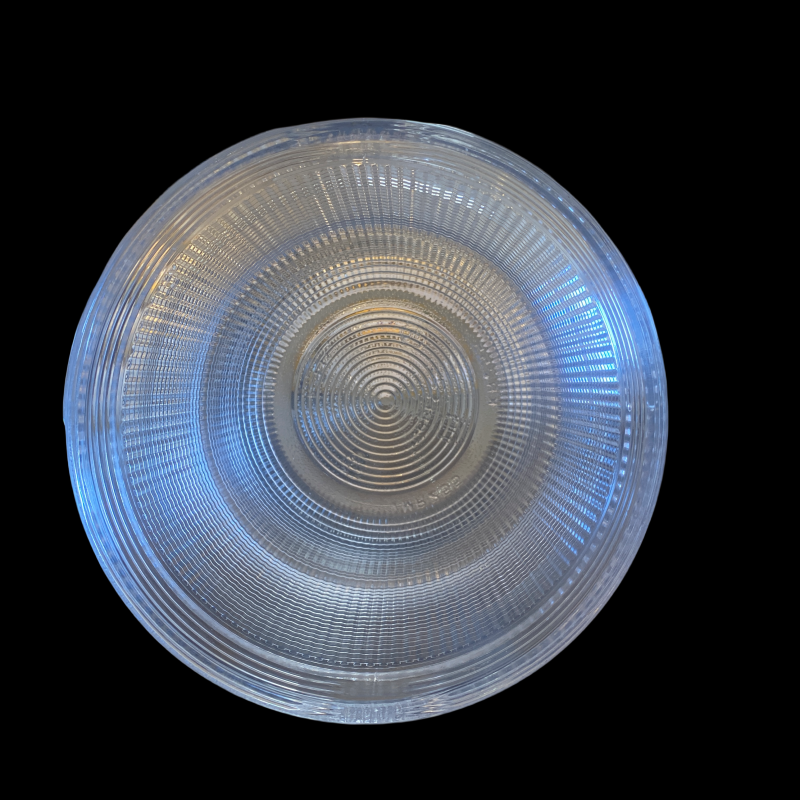

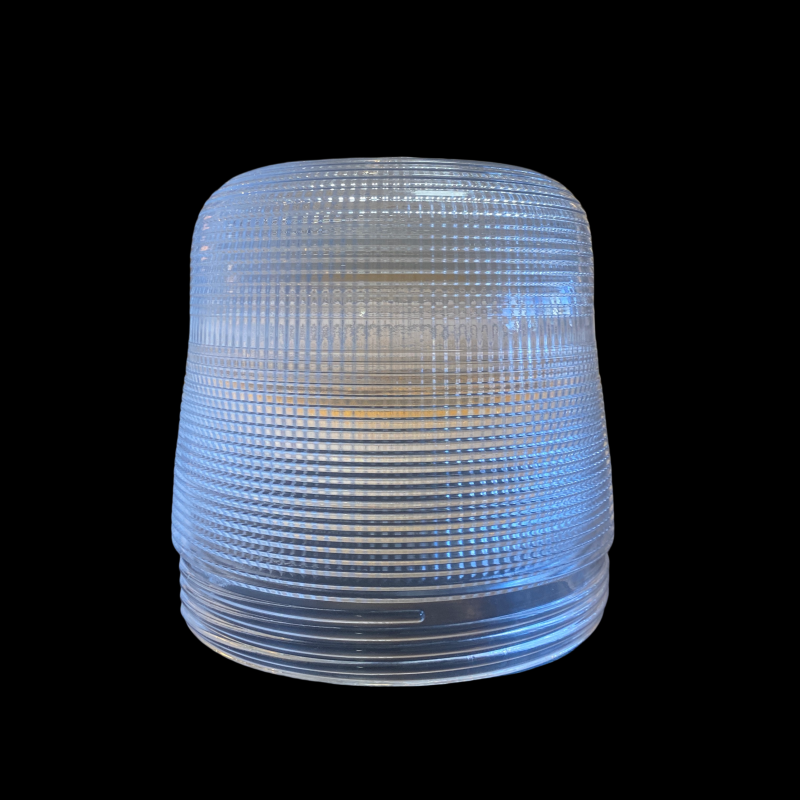

Re-defining functional lighting aesthetics, our explosion-proof lampshade merges decorative appeal with rigorous safety standards. The mould-pressed borosilicate construction ensures uniform pattern replication while providing shatter-resistant protection. Interior patterns diffuse light evenly, while exterior textures conceal surface wear. Engineered for Zone 1 hazardous areas, it withstands both mechanical impacts and explosive pressures without compromising its visual sophistication.

Features

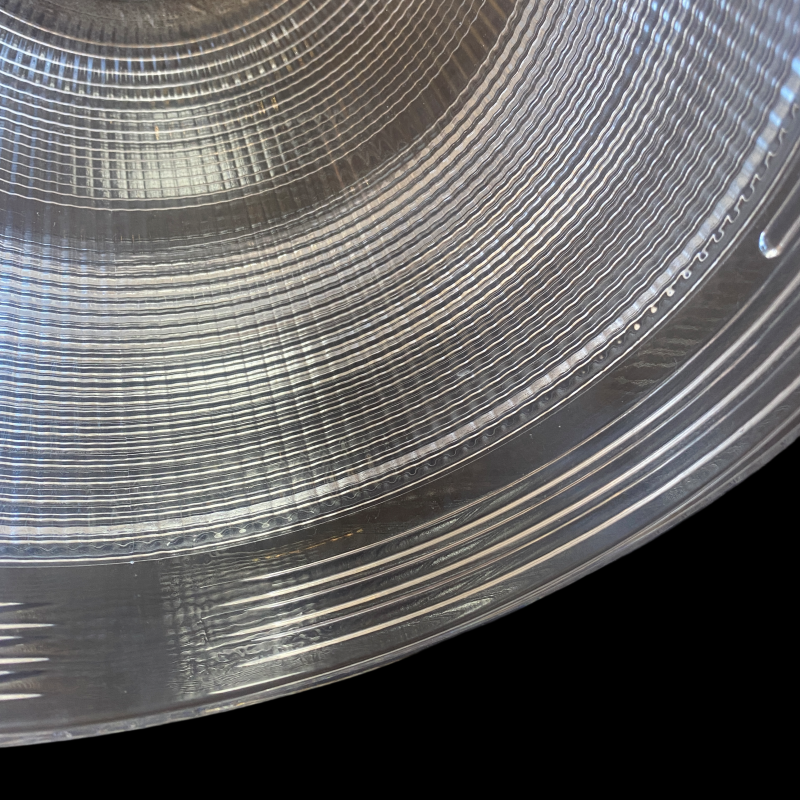

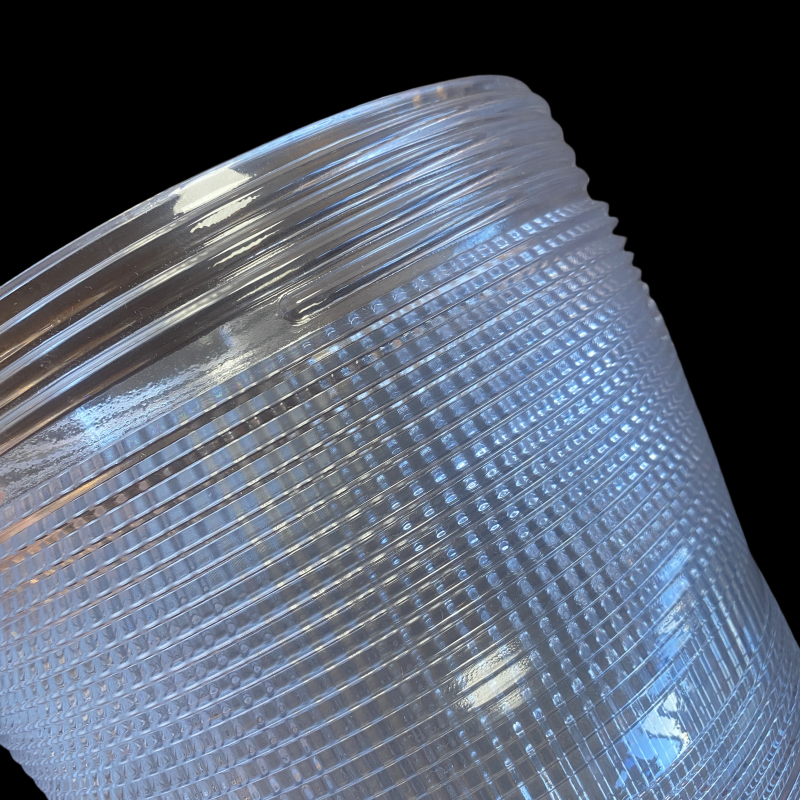

- Dual-surface patterning:

- Interior: Light-diffusing prismatic textures (20-80% haze adjustable)

- Exterior: Anti-slip decorative motifs (diamond, stipple, or custom designs)

- 3-12mm wall thickness options for varying impact requirements

- Custom optical effects:

- Frosted light diffusion

- Directional light control

- Colored glass interlayers

Advantages

- Hazardous Area Assurance

- ATEX/IECEx compliant for gas groups IIC (most stringent)

- Withstands 7 bar explosive overpressure (EN 13463-1)

- Non-incendive design prevents static buildup

- Advanced Pattern Technology

- CNC-machined moulds achieve 0.1mm pattern precision

- Dual-texture process maintains 85%+ light transmission

- Pattern depth customization (0.5-3mm) for desired shadow effects

- Material Superiority

- Borosilicate 3.3 glass composition resists:

- Hydrofluoric acid corrosion

- Thermal stress cracking

- UV degradation

- 4x harder than acrylic alternatives (7 Mohs)

- Borosilicate 3.3 glass composition resists:

- Commercial Versatility

- Brandable surface areas for corporate identity

Benefits

- Safety & Aesthetics Combined

- Eliminates glare while meeting explosion-proof mandates

- Conceals scratches and wear on exterior surfaces

- Maintains light output uniformity over decades

- Maintenance Optimization

- Self-cleaning patterns reduce dirt accumulation

- Threaded base enables tool-free replacement

- Inspection windows can be integrated

- Designer Flexibility

- Custom logo/text integration

- Gradient opacity designs available

- Cost Efficiency

- 50,000+ actuation cycles on threaded base

- Reduces luminaire replacement needs

- Lower insurance premiums for certified equipment

Application

- Oil & Gas:

- Drilling rig decorative lighting

- Refinery pathway illumination

- Chemical Processing:

- Reactor status lighting

- Pipeline marker lights

- Mining:

- Escape route lighting

- Equipment warning lights

- Specialty:

- Distillery ambient lighting

- Pharmaceutical cleanrooms

Technical Specifications

- Thermal Shock: Δ250°C

- Pattern Accuracy: ±0.05mm

- Light Transmission: 78-92% (pattern dependent)

Quality Control

- Each batch tested for:

- Thread engagement torque

- Pattern consistency