Introduction

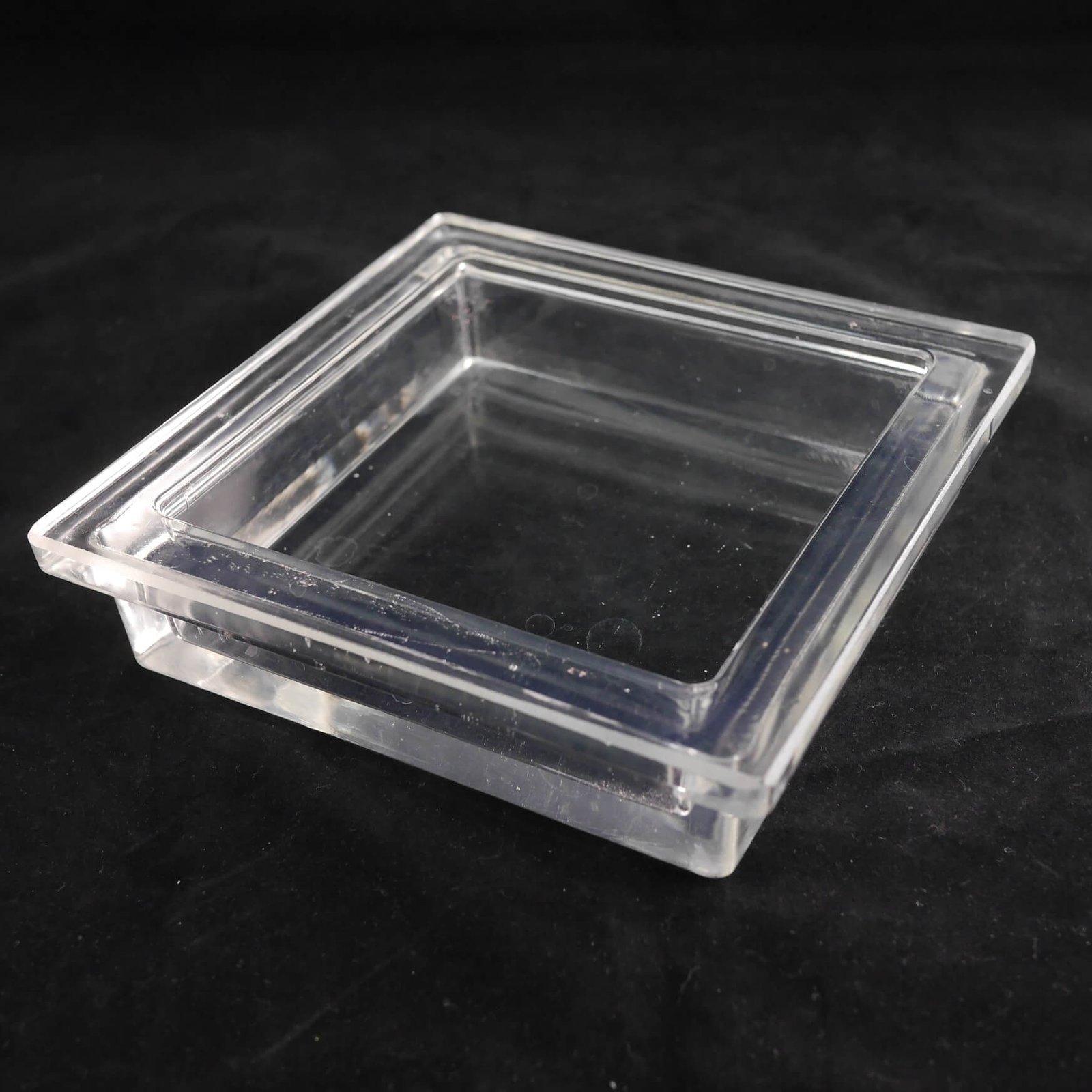

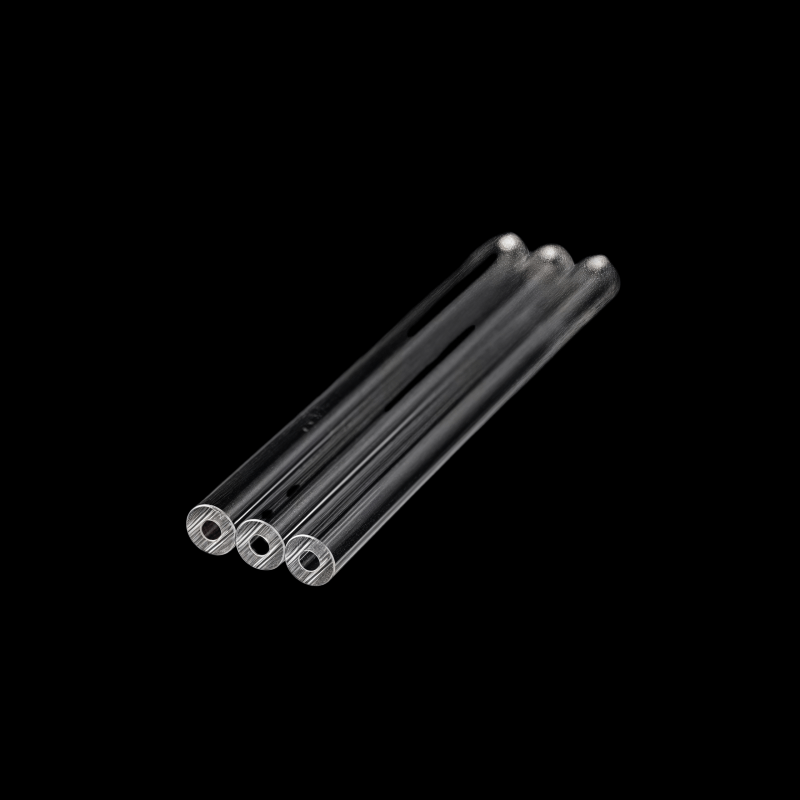

Designed to meet the rigorous demands of industrial and municipal lighting, our explosion-proof glass cover represents the perfect synergy of material science and precision engineering. The medium borosilicate composition (SiO₂ 78% + B₂O₃ 10%) provides superior thermal shock resistance compared to conventional glass, while the tempering process multiplies its mechanical strength. Unlike typical outdoor glass solutions, this product maintains optical clarity even after years of exposure to UV radiation, chemical vapors, and extreme weather cycles.

Features

- Industrial-grade medium borosilicate glass with low thermal expansion coefficient (4.5×10⁻⁶/K)

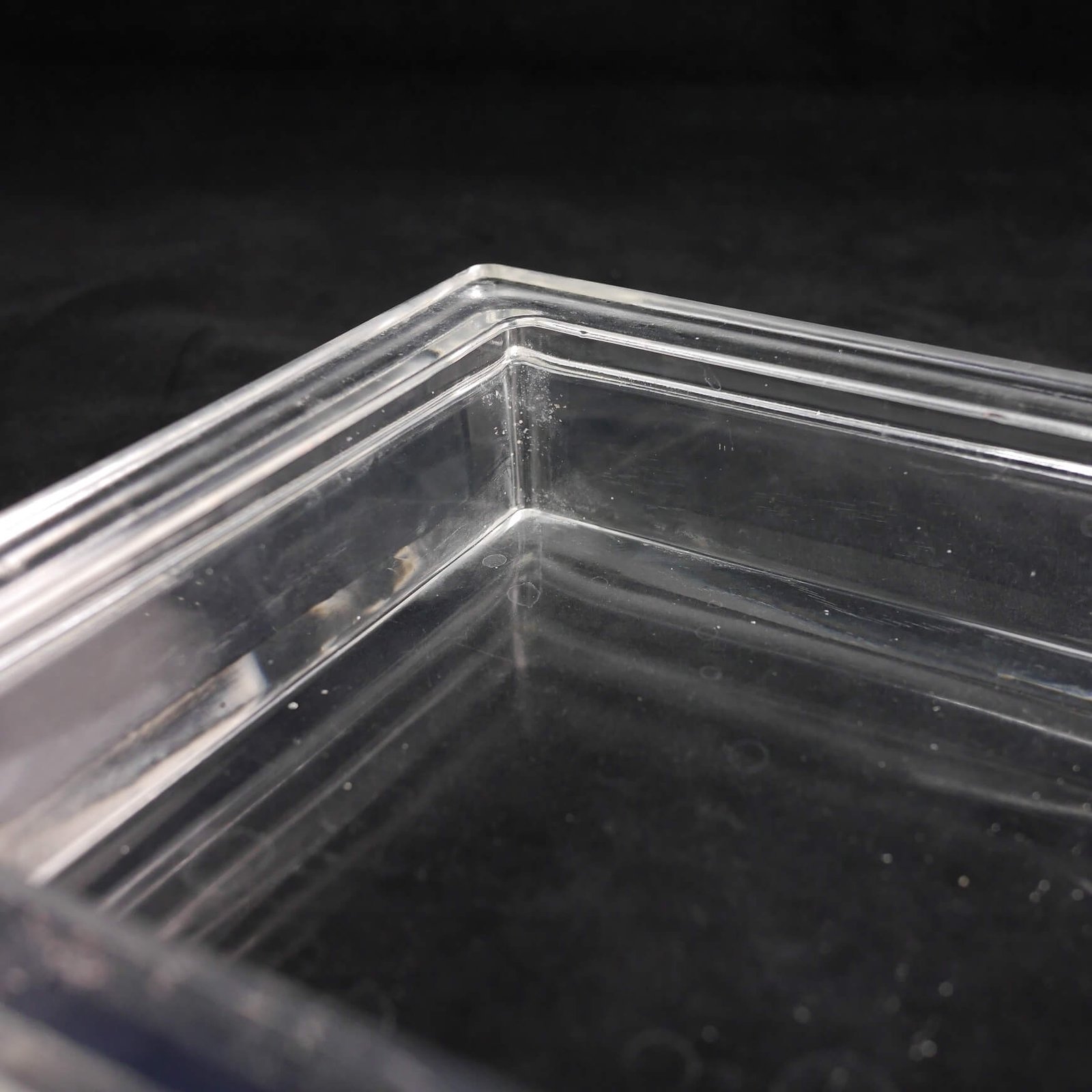

- Precision mould-pressed manufacturing ensures ±0.5mm dimensional tolerance

- Thermally toughened for 3× the strength of annealed glass

- Multiple edge finishing options: Machine-polished, seamed, or grooved for gaskets

- Custom surface treatments: Clear (standard), frosted, prismatic, or anti-reflective

Advantages

- Unmatched Safety Performance

- Withstands direct impacts (for example, 1kg steel ball dropped from 0.2m) without penetration

- Breaks into harmless granular fragments (meeting ANSI Z97.1 safety glazing standards)

- Maintains integrity during rapid temperature swings (Δ200°C instantaneous change)

- Superior Material Engineering

- Medium borosilicate formulation offers the optimal balance between thermal performance (withstands 300°C continuous) and production cost efficiency

- Acid-resistant surface (withstands pH 2-12 chemical exposure) for industrial environments

- Commercial Durability

- 5-8 year service life in coastal areas (tested per ASTM B117 salt spray standards)

- UV-stabilized to prevent yellowing or transparency loss over time

- Resists sand abrasion in desert applications (tested per ASTM D968)

- Design Flexibility

- Accommodates various mounting systems: compression gaskets, clamp rings, or screw-fastened

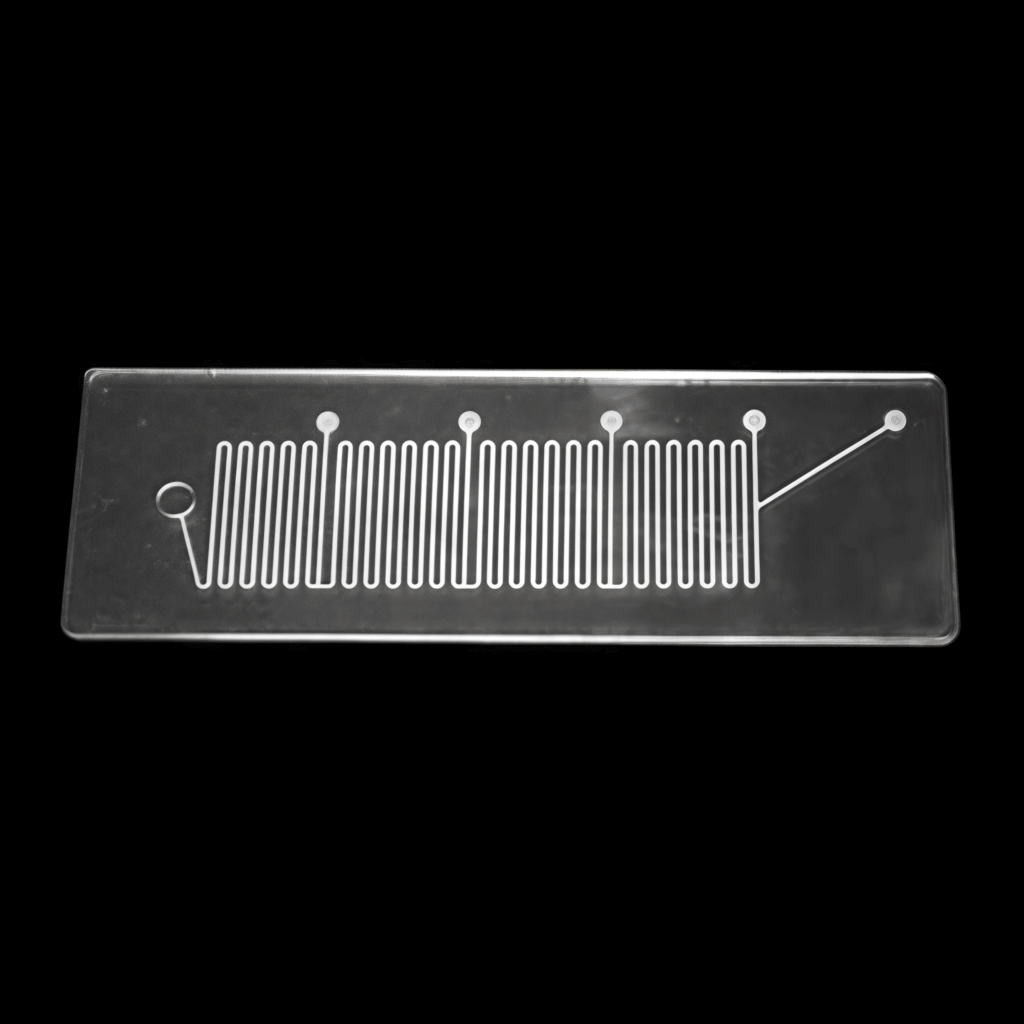

- Custom cutouts available for sensor integration or ventilation needs

- Laser etching capability for permanent labeling or branding

Benefits

- Risk Mitigation for Operators

- Eliminates glass shard hazards in explosion-prone areas (ATEX Zone 1 compliant)

- Reduces maintenance frequency and associated safety risks in hard-to-access installations

- Provides predictable failure mode for easier emergency response planning

- Total Cost of Ownership Savings

- 60% longer lifespan than soda-lime glass covers in equivalent environments

- Minimizes downtime with reliable performance in -30°C to 300°C range

- Interchangeable design allows reuse of mounting hardware during replacements

- Enhanced Optical Performance

- 92% light transmission (measured at 550nm wavelength) maximizes luminaire efficiency

- Optional anti-reflective coating reduces light loss to <5% in critical applications

- Matte finishes available to control glare in tunnel lighting installations

- Simplified Project Execution

- Pre-engineered solutions available for common hazardous location fixtures

- CAD models provided for seamless integration into lighting designs

- Batch-tested samples available for pre-installation verification

Application

- Oil & Gas: Explosion-proof luminaires for drilling platforms and refineries

- Transportation: Vibration-resistant covers for bridge and tunnel lighting

- Utilities: Corrosion-proof enclosures for wastewater treatment plants

- Mining: Impact-resistant lighting for underground operations