Introduction

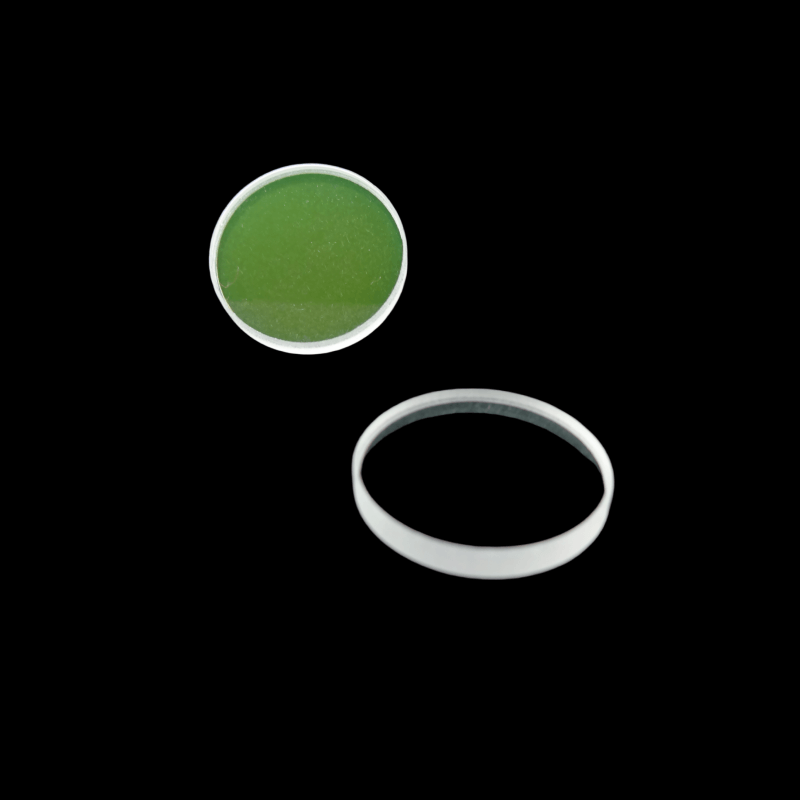

As the protective interface between high-intensity airfield lighting systems and harsh operating environments, our borosilicate glass lenses combine aerospace-grade material science with optical precision. The mould-pressed manufacturing process ensures consistent wall thickness for accurate light beam control, while the tempered borosilicate construction resists thermal shock from -40°C to 550°C. These covers meet the most demanding requirements for CAT II/III precision approach systems and high-traffic taxiways.

Features

- Aviation-grade borosilicate glass (SiO₂ 81% + B₂O₃ 13%) for extreme conditions

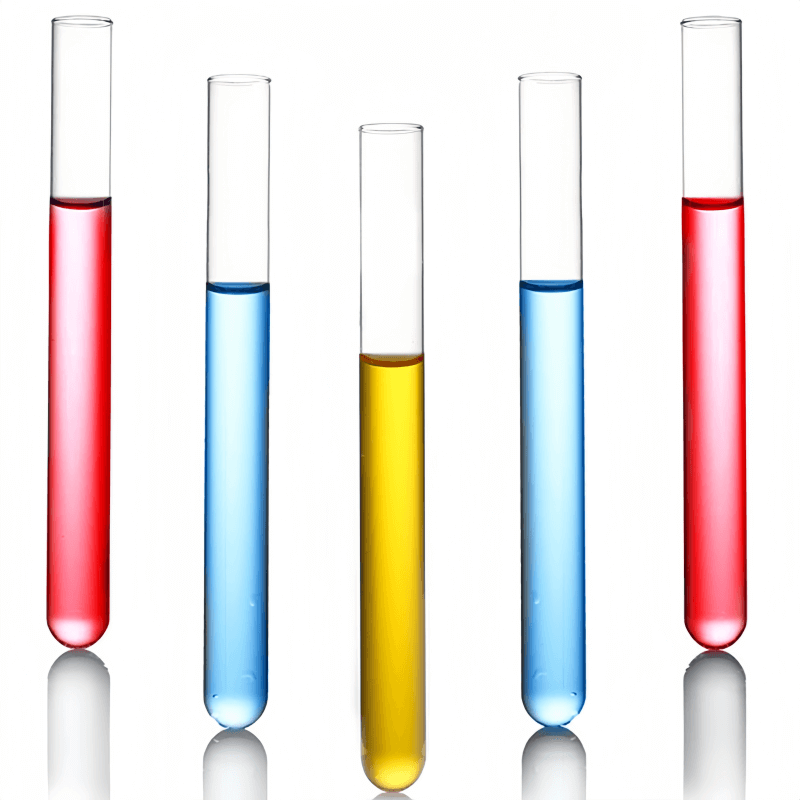

- FAA/ICAO-compliant color options:

• Red (610nm dominant wavelength)

• Blue (470nm)

• Green (505nm)

• Amber (590nm) - Precision optical surfaces:

• Fresnel lens patterns for beam focusing

• Prismatic light distribution options

• Anti-reflective coating available - Reinforced edge designs:

• Flanged for compression mounting

• Grooved for gasket sealing

• Threaded for screw-in fixtures

Advantages

- Aviation-Specific Durability

- Withstands 200mph jet blast (FAA AC 150/5345-46D) without deformation

- Resists hydraulic fluid and glycol-based de-icing chemicals (MIL-STD-810G)

- UV-stabilized to prevent color fading over 10+ years of sun exposure

- Precision Optical Performance

- Maintains ±3% chromaticity coordinates throughout service life

- Custom prismatic optics achieve precise beam angles (3°-20° adjustable)

- <2% light absorption for maximum intensity output

- Operational Safety

- Shatter-resistant design

- Fails visibly to ensure immediate maintenance response

- Non-glare surface treatment prevents pilot distraction

- Lifecycle Efficiency

- 50% longer service life than polycarbonate alternatives

- Interchangeable design allows retrofitting existing fixtures

- Modular replacement reduces downtime during repairs

Benefits

- Enhanced Airfield Safety

- Ensures consistent light output for precision approach path indicators (PAPI)

- Maintains color purity under all weather conditions (fog/rain/snow)

- Reduces FOD risk with secure mounting systems

- Maintenance Optimization

- Self-cleaning surface treatments reduce contamination buildup

- Quick-change design minimizes runway closure time

- Batch-tested consistency ensures uniform light arrays

- Customization Flexibility

- Laser-etched ID markings for asset management

- OEM branding options for system integrators

Application

- Runway Lights:

• Threshold identification

• Centerline illumination

• Touchdown zone markers - Taxiway Guidance:

• Edge lighting systems

• Rapid exit indicators

• Apron lead-in lines - Specialty Systems:

• Helipad perimeter lights

• Military airbase signaling

• Obstruction warning beacons