Introduction

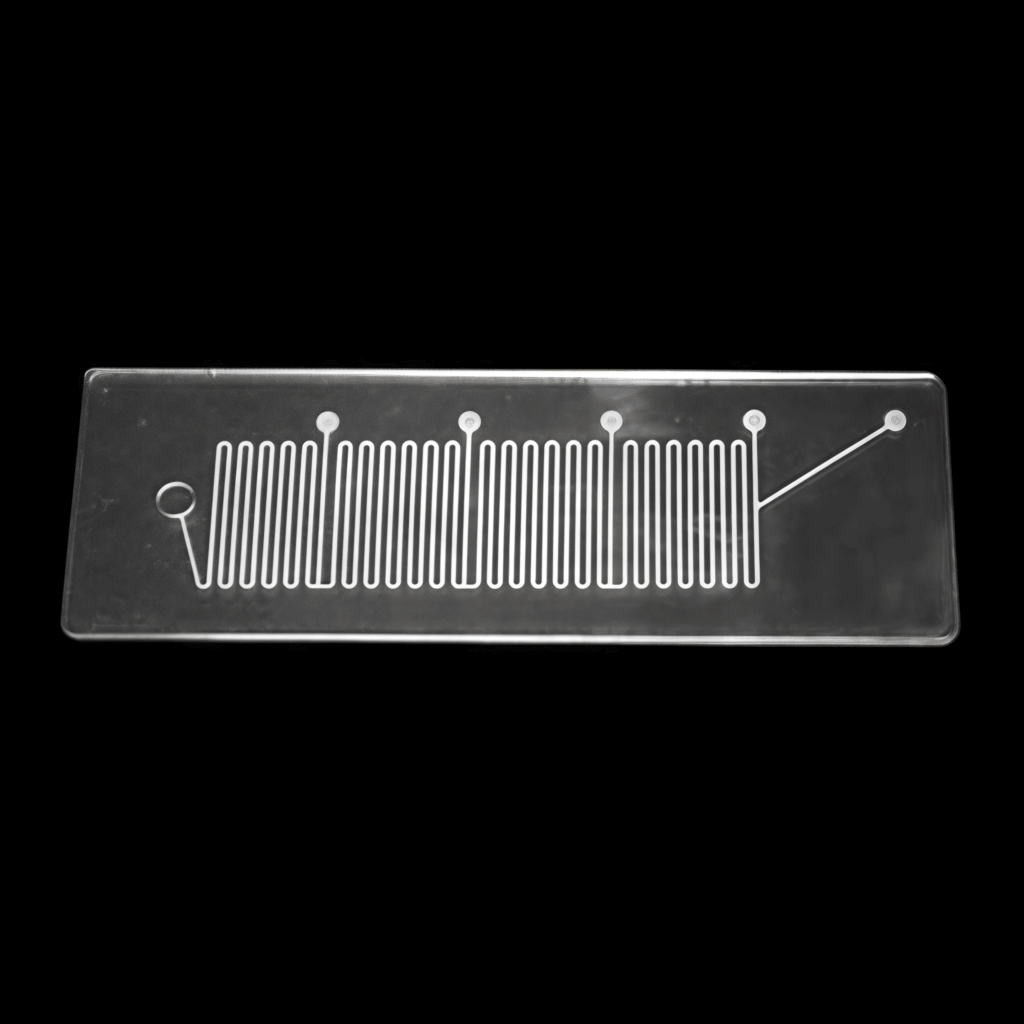

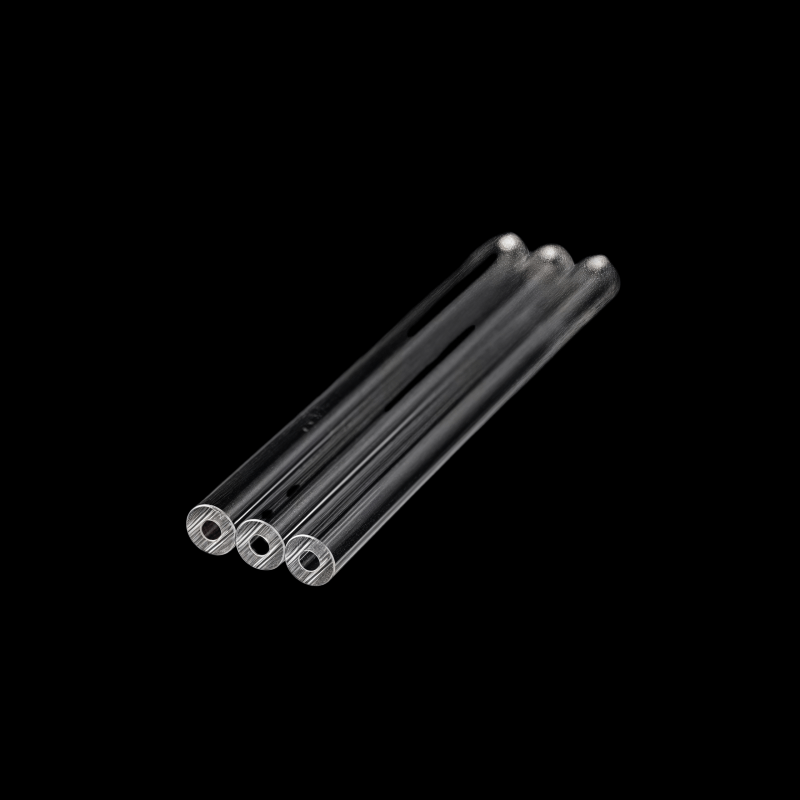

Our Borosilicate Glass Liquid Level Gauge is engineered to offer high-performance liquid level monitoring with superior durability and clarity. Produced through precision mould pressing, this gauge utilizes borosilicate glass known for its outstanding resistance to heat, chemicals, and mechanical stress. Its 110mm diameter and 17mm thickness are meticulously controlled to ensure consistent quality and fit for various liquid level indicator systems. Designed for reliability, the gauge maintains transparency for easy and accurate liquid observation in demanding industrial environments.

Features

- Made from premium borosilicate glass

- Mould pressed for consistent shape and quality

- Dimensions: 110mm diameter x 17mm thickness

- High resistance to thermal shock and chemical corrosion

- Smooth and customizable edge finishing

- Precision size control for compatibility

- Customizable shapes and sizes based on client needs

Advantages

- Robust Thermal and Chemical Resistance: Borosilicate glass withstands harsh conditions, ensuring stable performance and longevity in aggressive liquid environments.

- Precision Manufacturing: Mould pressing guarantees uniform thickness and dimensions, facilitating easy integration into existing liquid level gauge assemblies.

- Enhanced Durability: The strong glass construction reduces risk of cracks or damage, lowering maintenance frequency and costs.

- Customizable Design: Flexibility in shape, size, and edge treatment allows the product to be tailored for specialized equipment and client specifications.

- Reliable Optical Clarity: Ensures clear visibility of liquid levels, enabling accurate monitoring and operational safety.

Benefits

- Improved Operational Safety: Clear and durable liquid level indication helps prevent overflow or dry-run issues, protecting equipment and personnel.

- Long-Term Cost Efficiency: Reduced replacement and repair needs lead to lower lifecycle costs.

- Ease of Installation and Replacement: Precision dimensions and customizable options ensure compatibility and smooth installation in various systems.

- Versatile Application: Suitable for a broad range of industrial liquid level monitoring tasks, including chemical, pharmaceutical, and food processing industries.

- OEM/ODM Support: Capable of meeting bespoke production demands with flexible minimum order quantities.

Application

Ideal for use in liquid level gauges across industries such as chemical processing, oil and gas, pharmaceuticals, and water treatment, where clear and reliable liquid monitoring is critical for safe operation.